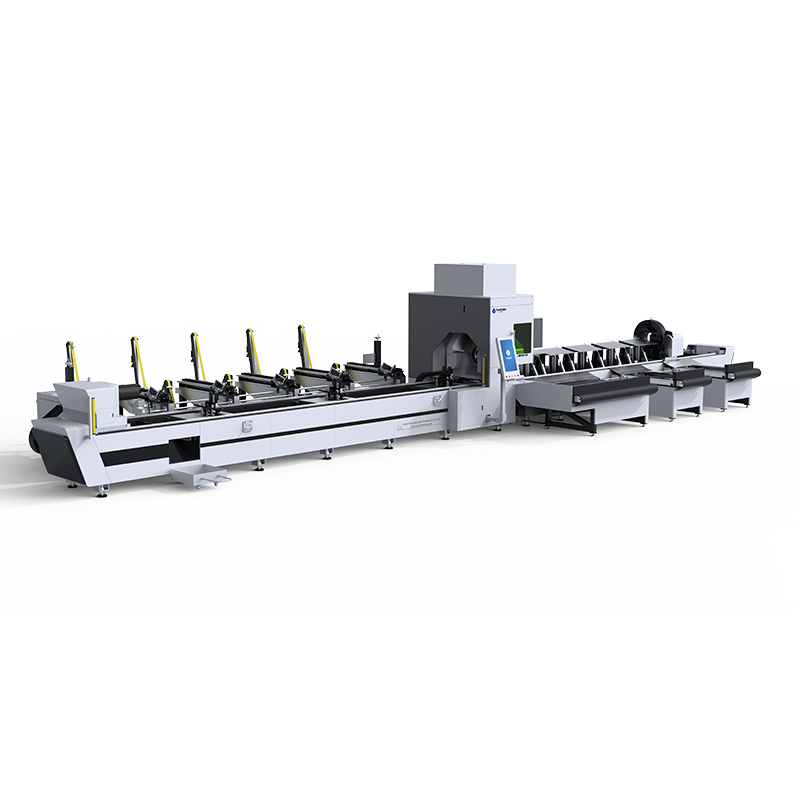

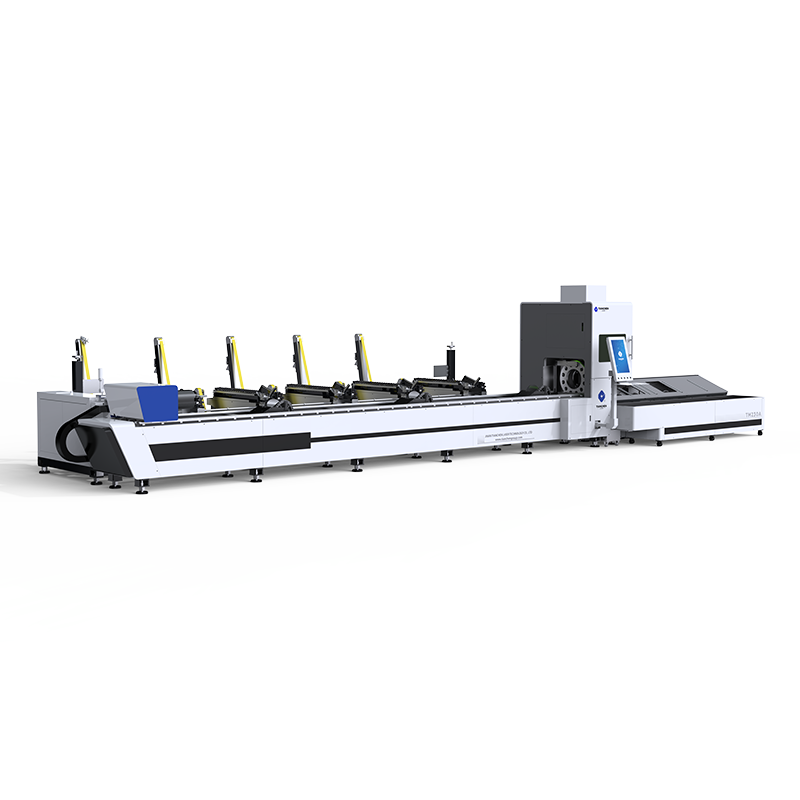

A curved surface cutting industrial laser cutting machine from Tianchen Laser is designed to tackle the unique challenges of cutting curved or 3D metal surfaces, combining advanced laser technology with multi-axis motion control to achieve precise results. As a high-tech enterprise with 29 years of experience since 1995, Tianchen Laser has developed a curved surface cutting industrial laser cutting machine that features 5-axis or 6-axis motion systems, 3D scanning capabilities, and real-time surface tracking, allowing it to follow the contours of curved metal parts—ideal for industries like automotive body manufacturing, aerospace component production, and custom metal fabrication, where curved surface cutting industrial laser cutting machine is essential for processing parts such as curved panels, tubular structures, and complex 3D components. This curved surface cutting industrial laser cutting machine integrates software that converts 3D CAD models into cutting paths, ensuring that the laser beam maintains optimal distance and angle across every point of the curved surface, delivering consistent cut quality. Produced at Tianchen Laser’s intelligent manufacturing base with an annual capacity of over 10,000 units, the curved surface cutting industrial laser cutting machine undergoes rigorous testing to handle diverse metals, including steel, aluminum, and titanium, maintaining reliability across over 100 countries and regions. With a customer-centered approach, the company tailors this curved surface cutting industrial laser cutting machine to specific curvature radii and part sizes, offering adjustable scanning speeds and laser power to match surface complexity. Whether cutting shallow curves on automotive fenders or deep contours on aerospace parts, a curved surface cutting industrial laser cutting machine from Tianchen Laser delivers exceptional precision, supported by the company’s commitment to quality and service, including technical support for 3D path optimization. A curved surface cutting industrial laser cutting machine from Tianchen Laser is more than a tool; it’s a 3D cutting solution that expands the possibilities of industrial metal processing, enabling manufacturers to produce curved components with accuracy and efficiency, solidifying the company’s position as a global leader in intelligent metal forming solutions.

Copyright © 2024 by JINAN TIANCHEN LASER TECHNOLOGY CO.,LTD