With new technologies being introduced, efficiency and product quality in operational processes increase. One such innovation that is gaining a lot of traction among engineers is the laser tech especially used for steel cutting machines. This article analyzes how the advancement of steel cutting machines is being enabled by laser technology. More importantly, it seeks to provide insights into the benefits, applications as well as the future trends in this sector.

Laser technology has completely changed how steel cutting is done, using fantasies of speed and substantial quality that were unimaginable with the older technology. To put it simply, laser cutting is simply the melting or vaporization of material with the use of lased concentrated beams and as a result, cuts are left clean and accurate. Not only do the improves cuts quality but it also reduces production costs incurred by cutting. The demand for environmentally friendly manufacturing approaches increases with the increase in industries, making laser cutting machines perfect.

The most potent gain from introducing laser technology in steel cutting is its capacity to work with complicated geometrical details. Other more traditional cutting processes find it hard to deal with intricate designs and this makes times of production to take longer and cost higher. Yet however, cutting machines using lasers have no problem following detailed diagrams ensuring that the out matched designs are of very intricate detail. Such ability is highly relevant in sectors where precision is of the utmost importance such as the automotive or aerospace sectors.

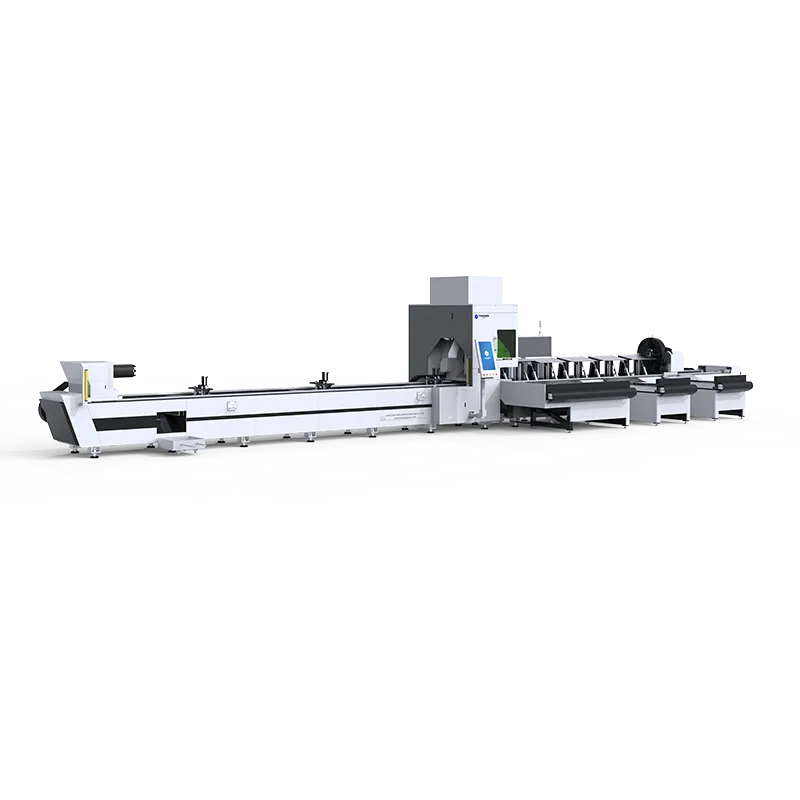

Moreover, laser cutting machines are fast and always efficient. The laser beams can be moved at a comparatively higher rate than any other technique and thus the cut is done at a faster pace, which in turn results in a faster production time. This efficiency not only contributes to productivity improvement but also allows manufacturers to adjust to the market more easily. The current business environment has placed the pressure on businesses to produce products faster than what was previously required, thus the use of laser technology comes in handy.

Additionally, the flexibility that laser cutting machines bear permits them to cut other materials besides steel. From manufacturing equipment to automotive leather, laser technology can facilitate cutting a variety of substrates making it a highly efficient machinery. This versatility not only broadens possible applications but also enables a business to consolidate movements of investing in a single cutting machine to perform various material cutting as the business sector demands.

As we glance towards the future, the trends in laser technology are bound to give eye sore results. Advancements such as fiber lasers and further automated features are set to improve the effectiveness of steel cutting machines even more. More efficient and economical than alternatives, fiber lasers are manufacturers’ materias of choice. In addition, injecting AI and, later, lasers with ML capabilities into the cutting processes will guarantee more efficiency, minimal idle time and greater output levels.

In conclusion, the importance of laser technology in terms of how effective steel cutting machines are, is quite relevant. Indeed, laser cutting is one of the most important aspects of manufacturing today due to the accuracy, effectiveness, and wide range of applications it possesses. There is no doubt that there will be further advances in this technology and it will be vital for industries to keep up in order to stay competitive in a fast paced marketplace. The shift to using lasers means that manufacturers will not only expand their business capabilities but also answer the ever growing questions of quality and sustainability that buildings processes need to be able to handle.