In the dynamic landscape of manufacturing, precision and efficiency are paramount, and laser-based solutions for cutting metallic materials have emerged as a transformative force. As industries ranging from automotive to construction demand higher accuracy, faster production, and more flexible processes, the role of advanced laser cutting technology has become irreplaceable. Tianchen Laser, a pioneering high-tech enterprise with nearly three decades of experience, stands at the forefront of delivering innovative laser cutting solutions tailored to global customers’ needs.

The Evolution of Laser-Based Metal Cutting – From Innovation to Mainstream

The journey of laser-based metal cutting has evolved from a niche technology to a mainstream manufacturing essential. In the early days, traditional cutting methods such as plasma or mechanical cutting dominated the market, but they often fell short in terms of precision, material waste, and adaptability to complex designs. The advent of fiber laser technology revolutionized the sector, offering unmatched accuracy and efficiency. Since its establishment in 1995, Tianchen Laser has been a key contributor to this evolution, leveraging decades of industry insight to refine laser cutting solutions that meet the evolving demands of global manufacturers. Today, laser-based solutions for cutting metallic materials are no longer a luxury but a necessity for businesses aiming to stay competitive in a fast-paced market.

Tianchen Laser’s Core Competencies – Building Trust Through Quality and Innovation

As a high-tech enterprise specialized in intelligent metal forming equipment, Tianchen Laser’s core strength lies in its integrated approach to research, development, production, and sales. The company boasts an intelligent manufacturing base that supports an annual production capacity of over 10,000 units for its main products, ensuring reliable supply to customers worldwide. Over the past 29 years, Tianchen Laser has adhered to a quality and service-oriented, customer-centered philosophy, expanding its business to more than 100 countries and regions. Its commitment to innovation is evident in the acquisition of over 20 software copyrights and patents since 2019, while numerous provincial and national honors attest to its industry leadership. For global customers, Tianchen Laser is not just a supplier but a trusted partner offering comprehensive laser cutting solutions.

Key Advantages of Tianchen’s Laser Cutting Equipment – Precision, Efficiency, and Versatility

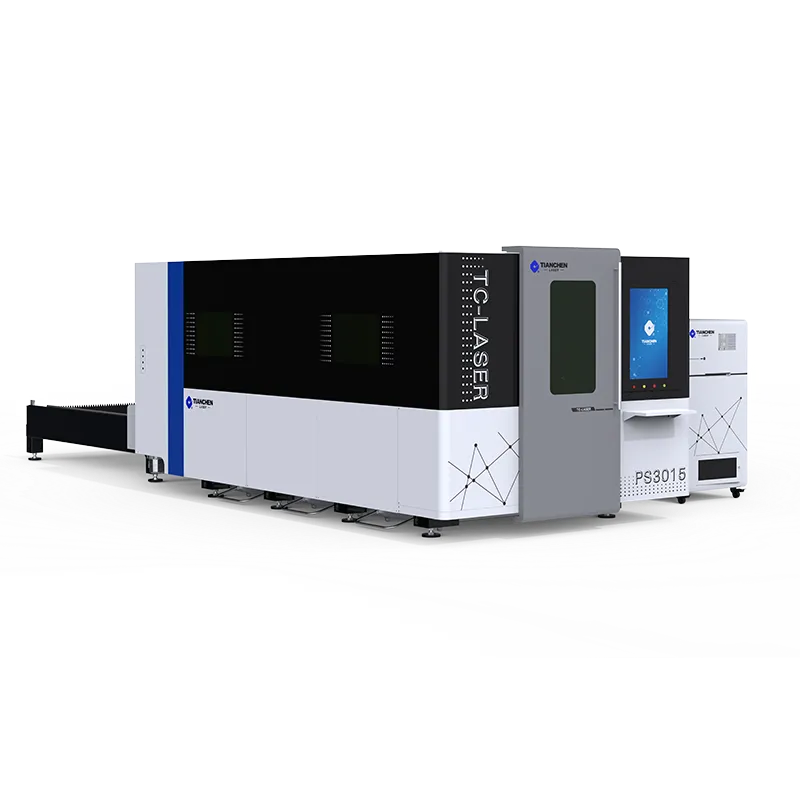

Tianchen Laser’s diverse product lineup is designed to cater to varied metal cutting needs, combining advanced technology with practical functionality. The cost-effective NS3015 model is ideal for businesses seeking high-quality metal processing at an affordable price, balancing performance and budget. The M230 stands out for its robust build and efficient cutting mechanism, delivering consistent results across various metal cutting tasks. For large-scale industrial projects, the FB12525 large-format laser cutting machine merges power and precision, meeting the demands of heavy-duty applications. The PM3015 represents the pinnacle of the company’s technology, integrating enhanced features to boost productivity and product quality. Additionally, technologies like servo follow-up and front clamp override enhance operational flexibility, while customized solutions ensure that each customer’s unique requirements are met. These advantages make Tianchen’s laser-based solutions for cutting metallic materials a top choice across industries.

Industry-Specific Applications – Powering Diverse Sectors

Laser cutting solutions by Tianchen Laser have found wide application in key industries, driving efficiency and innovation. In the agricultural machinery and heavy machinery sectors, the high precision of laser cutting ensures the reliability of critical components. In automotive manufacturing, the technology supports the production of complex parts with tight tolerances, contributing to vehicle performance. The construction and construction machinery industries benefit from the speed and accuracy of Tianchen’s equipment, aligning with the sector’s shift toward high-efficiency manufacturing. Moreover, the integration of laser cutting machines with automated tower storage equipment streamlines material handling and storage, creating a seamless production workflow. These industry-specific applications demonstrate the versatility and practical value of Tianchen’s laser cutting solutions.

Future Trends in Laser-Based Metal Cutting – Tianchen’s Ongoing Commitment

The future of laser-based metal cutting is marked by increased automation, intelligence, and sustainability. As manufacturers pursue smarter production lines, Tianchen Laser is poised to lead the way with its professional R&D team, continuously innovating to integrate cutting-edge technologies into its solutions. The company’s focus on customer needs ensures that its future products will not only enhance precision and speed but also reduce energy consumption and environmental impact. With the global manufacturing landscape evolving rapidly, Tianchen Laser remains dedicated to advancing laser cutting solutions, helping customers adapt to changing market demands and achieve long-term growth.

As the demand for high-quality metal cutting continues to grow globally, Tianchen Laser remains at the forefront of delivering innovative, reliable laser-based solutions for cutting metallic materials. Its 29-year legacy of quality, innovation, and customer-centricity, combined with a global presence and diverse product portfolio, positions the company as a leader in the industry. For businesses seeking to elevate their metal cutting processes, Tianchen Laser offers not just equipment but comprehensive solutions that drive efficiency, quality, and competitiveness in the global market.

Table of Contents

- The Evolution of Laser-Based Metal Cutting – From Innovation to Mainstream

- Tianchen Laser’s Core Competencies – Building Trust Through Quality and Innovation

- Key Advantages of Tianchen’s Laser Cutting Equipment – Precision, Efficiency, and Versatility

- Industry-Specific Applications – Powering Diverse Sectors

- Future Trends in Laser-Based Metal Cutting – Tianchen’s Ongoing Commitment