1. Introduction: The Backbone of Modern Manufacturing – Steel Fabrication and Cutting Challenges

Steel fabrication stands as a cornerstone of global industries, from automotive manufacturing and construction to heavy machinery and agricultural equipment. The quality and efficiency of steel cutting directly determine production outcomes, yet traditional cutting methods such as plasma or mechanical cutting have long struggled with limitations—low precision, material waste, and slow processing speeds. In this context, laser technology has emerged as a transformative force, redefining the capabilities of the steel cutting machine. For nearly three decades, enterprises like Tianchen Laser have been at the forefront of this revolution, leveraging innovation to address the evolving needs of manufacturers worldwide.

2. Core Advantages: How Laser Technology Transforms Steel Cutting

Laser technology has reshaped steel cutting by addressing the critical pain points of traditional methods, offering four key advantages that elevate the steel cutting machine to new heights. First, precision is unparalleled—laser cutting machines deliver micron-level accuracy, ensuring clean, burr-free edges that reduce post-processing work. This is particularly vital for high-precision applications like automotive parts and construction machinery components. Second, efficiency is dramatically improved: advanced laser systems cut through thick steel plates at speeds far exceeding traditional methods, with Tianchen Laser’s models boasting consistent performance even for large-format tasks. Third, cost-effectiveness shines through reduced material waste—laser beams minimize kerf width, maximizing the utilization of raw steel, while lower energy consumption and maintenance needs cut long-term operational costs. Finally, flexibility makes laser steel cutting machines adaptable to diverse requirements, from small-batch custom parts to mass-produced components, supporting industries ranging from aerospace to agricultural machinery.

3. Tianchen Laser: Decades of Expertise in Laser Steel Cutting Solutions

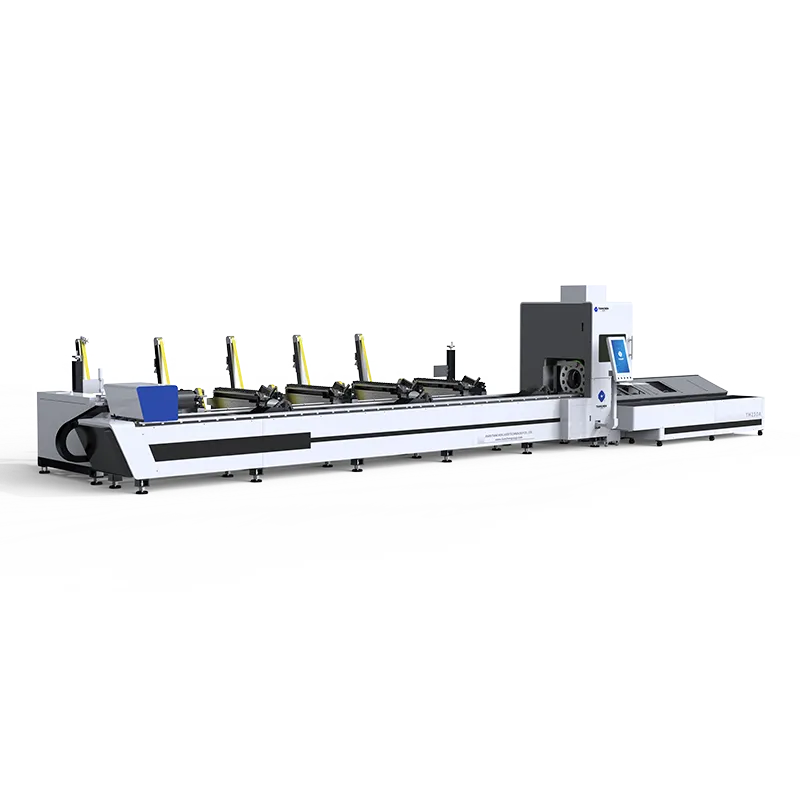

Founded in 1995, Tianchen Laser is a high-tech enterprise dedicated to the R&D, production, and sales of intelligent metal forming equipment, with a focus on delivering top-tier steel cutting machine solutions. Over 29 years of development, the company has built an intelligent manufacturing base with an annual production capacity of over 10,000 units, ensuring reliable supply for global customers. Its product lineup covers a full range of laser cutting machines, including cost-effective models like the NS3015, robust options such as the M230, large-format solutions like the FB12525, and advanced systems like the PM3015. These steel cutting machines integrate cutting-edge technologies—from servo follow-up systems to front clamp override—delivering precision and efficiency that set industry benchmarks.

Adhering to a quality and service-oriented, customer-centered philosophy, Tianchen Laser has expanded its business to more than 100 countries and regions. The company’s R&D team, which has secured over 20 software copyrights and patents, continuously innovates to enhance product performance. For example, the all-new P Series laser cutting machines are hailed as “the king of efficiency among peer products,” while the FB Series bevel cutting machines are renowned for their precision in complex steel fabrication tasks. This commitment to innovation and customer satisfaction has made Tianchen Laser a trusted partner for manufacturers seeking reliable steel cutting solutions.

4. Far-Reaching Impacts of Laser Technology on Steel Fabrication Industry

The adoption of laser technology in steel cutting machines has had a profound impact on the global steel fabrication industry. It has boosted production efficiency by reducing processing time and post-treatment work, enabling manufacturers to meet tight deadlines without compromising quality. For industries like construction machinery, where high-efficiency and high-quality manufacturing are critical, laser-cut steel components have become indispensable, driving the industry toward more advanced development. Additionally, laser cutting supports sustainable manufacturing by minimizing material waste and energy consumption, aligning with global environmental goals.

Moreover, laser technology has lowered the barrier to entry for complex steel fabrication, allowing small and medium-sized enterprises to access high-precision cutting capabilities at affordable costs—thanks to cost-effective models like Tianchen Laser’s NS3015. This democratization of technology has fostered innovation across industries, from automotive manufacturing to agricultural machinery, creating new opportunities for growth.

5. Future Trends: Laser Cutting’s Evolution in Steel Processing

The future of steel cutting machines lies in deeper integration of laser technology with intelligence and automation. Tianchen Laser is already leading this trend by developing automated production line solutions, including compatibility with automated tower storage equipment for seamless material handling. Future laser steel cutting machines will feature higher power outputs, enabling faster cutting of thicker steel plates, and smarter control systems that optimize cutting parameters in real time. As industries demand more customized, efficient, and sustainable solutions, laser technology will continue to evolve, with enterprises like Tianchen Laser driving innovation to meet these needs.

6. Conclusion

Laser technology has undoubtedly revolutionized the steel cutting machine, transforming steel fabrication from a labor-intensive, low-precision process to a high-efficiency, high-quality core of modern manufacturing. Tianchen Laser, with its 29 years of expertise, global presence, and commitment to innovation, stands as a key enabler of this transformation. As the industry moves toward intelligence and sustainability, laser-powered steel cutting machines will remain indispensable, and enterprises like Tianchen Laser will continue to lead the way with reliable solutions and exceptional service.