Metal fabrication has long been a cornerstone of global industrial development, but traditional cutting methods—such as plasma cutting or mechanical shearing—often struggled with inefficiencies, imprecision, and limited scalability. In an era where manufacturing demands speed, accuracy, and cost-effectiveness, the CNC laser cutter for metal has emerged as a transformative force, redefining how industries approach metal processing. Tianchen Laser, a high-tech enterprise founded in 1995, has been at the forefront of this revolution, leveraging 29 years of expertise in research, development, production, and sales of intelligent metal forming equipment to deliver cutting-edge solutions that elevate fabrication processes worldwide.

The Core Advantages of CNC Laser Cutters for Metal: Precision and Efficiency Redefined

The most striking transformation brought by the CNC laser cutter for metal lies in its unmatched precision and efficiency. Unlike traditional methods that leave rough edges or require secondary finishing, CNC laser cutters use focused laser beams to achieve micron-level accuracy, ensuring consistent quality across every workpiece. For industries like automotive manufacturing and heavy machinery—where component precision directly impacts safety and performance—this level of accuracy is non-negotiable. Tianchen Laser’s CNC laser cutters, such as the advanced PM3015 model and the large-format FB12525, embody this advantage: the former integrates state-of-the-art laser technology to boost productivity, while the latter combines power and precision for large-scale industrial projects.

Efficiency is another key driver of transformation. Tianchen Laser’s CNC laser cutters feature efficient cutting mechanisms and servo follow-up systems, enabling faster processing speeds without compromising quality. With an annual production capacity exceeding 10,000 units, the company ensures its machines are built for durability and continuous operation—critical for meeting the high-volume demands of modern fabrication. For businesses seeking cost-effective solutions, models like the NS3015 offer quality metal processing at an affordable price, proving that efficiency and accessibility can go hand in hand.

Intelligent Integration: How CNC Laser Cutters Streamline Automated Production Lines

Modern fabrication processes are no longer isolated operations—they require seamless integration into automated production lines, and the CNC laser cutter for metal is central to this synergy. Tianchen Laser’s commitment to providing automated production line solutions is reflected in its intelligent manufacturing base and integration with innovative equipment like automated tower storage systems. These systems work in tandem with CNC laser cutters to optimize material unloading, storage, and retrieval, reducing downtime and streamlining the entire workflow.

The company’s 20+ software copyrights and patents underscore its focus on technological innovation. Tianchen Laser’s CNC laser cutters are equipped with intelligent control systems that allow for real-time monitoring, parameter adjustment, and remote operation—empowering manufacturers to manage production more flexibly. This intelligent integration not only reduces human error but also enhances scalability, enabling businesses to adapt to changing market demands quickly. For global customers across 100+ countries and regions, this means a more reliable, efficient, and future-ready fabrication process.

Global Trust: Tianchen Laser’s CNC Laser Cutters for Diverse Industrial Applications

The transformative impact of the CNC laser cutter for metal extends across diverse industries, from agricultural machinery and construction to automotive manufacturing and construction machinery. Tianchen Laser’s customer-centric approach and quality-oriented philosophy have made its products a trusted choice for businesses worldwide. The FB series bevel cutting machines, renowned for their precision and efficiency, are widely used in construction machinery manufacturing—an industry where high-quality, high-efficiency manufacturing technology is now a core development trend.

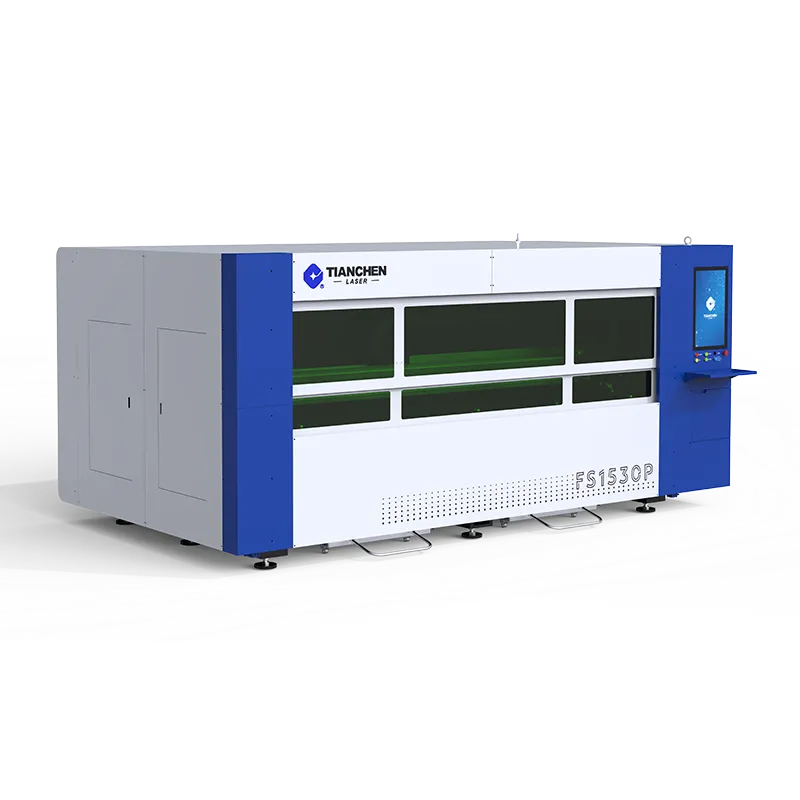

Over 29 years of rapid growth, Tianchen Laser has expanded its business to more than 100 countries and regions, adhering to the principle of prioritizing quality and service. Whether it’s a small business in need of a cost-effective solution or a large enterprise requiring large-format cutting capabilities, the company’s full range of CNC laser cutters (including P SERIES, FB SERIES, TM SERIES, and FS SERIES) caters to every need. This versatility, combined with reliable performance and excellent after-sales service, has solidified Tianchen Laser’s reputation as a leading player in the global laser industry.

As the global manufacturing industry shifts toward smarter, more sustainable production, the CNC laser cutter for metal will remain a critical driver of innovation. Tianchen Laser’s 29-year legacy of excellence, commitment to customer satisfaction, and continuous technological advancement ensure that its CNC laser cutters will continue to transform fabrication processes—helping businesses across the globe achieve higher efficiency, better quality, and greater success. In the journey of industrial evolution, Tianchen Laser is not just providing machines; it’s empowering the future of metal fabrication.