Modern manufacturing is undergoing a precision-driven revolution, where the demand for high-precision, efficient, and flexible processing solutions has never been higher. At the heart of this transformation lies the CNC engraving machine, a technology that bridges digital design and physical production, redefining the boundaries of what’s possible in metal forming and beyond. For Tianchen Laser, a high-tech enterprise founded in 1995 and specialized in intelligent metal forming equipment, the CNC engraving machine is not just a product—it’s a core pillar of its commitment to delivering global customers with advanced metal forming and automated production line solutions.

The Core Value of CNC Engraving Machine in Modern Manufacturing

In today’s fast-paced manufacturing landscape, precision is no longer a competitive edge but a basic requirement—especially in industries like automotive manufacturing, agricultural machinery, and heavy machinery, where even a tiny deviation can affect product performance and safety. The CNC engraving machine addresses this need by translating complex CAD designs into precise physical parts with unparalleled consistency.

Tianchen Laser, with 29 years of rapid growth, has elevated the role of CNC engraving machines in this ecosystem. Equipped with an intelligent manufacturing base, the company boasts an annual production capacity of over 10,000 units for its main products, ensuring it can meet the global demand for high-quality CNC engraving solutions. What sets Tianchen Laser apart is its customer-centered approach: every CNC engraving machine is designed not just to meet industry standards, but to adapt to the unique needs of customers across more than 100 countries and regions. Whether a customer requires small-batch precision components or large-scale industrial parts, the CNC engraving machine from Tianchen Laser serves as a reliable bridge between design concepts and practical production.

Technical Excellence: What Makes Tianchen Laser’s CNC Engraving Machine Stand Out

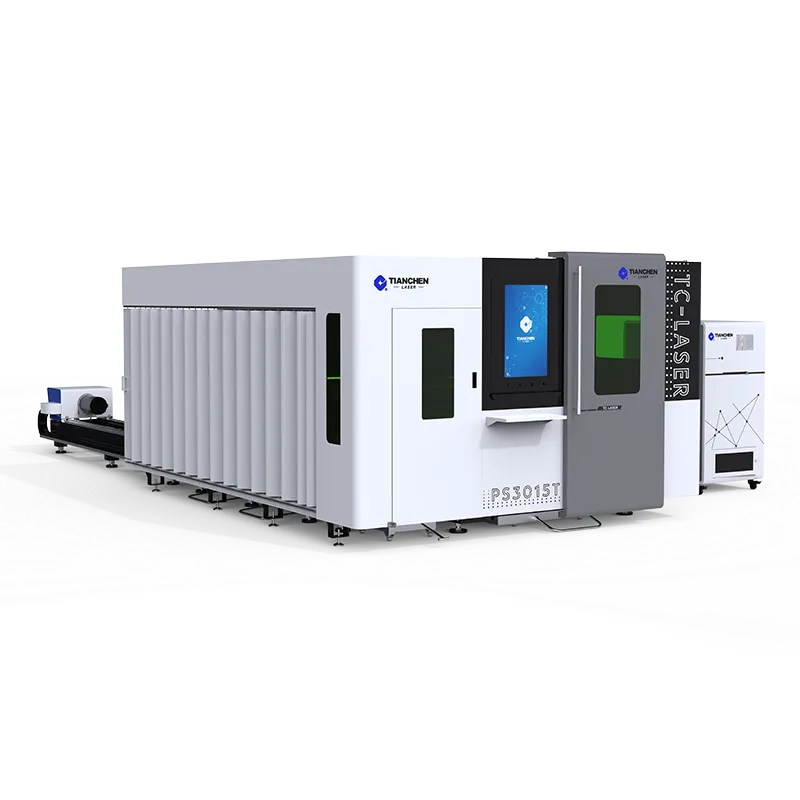

Precision in CNC engraving machines is built on advanced components and intelligent design—and Tianchen Laser leaves no stone unturned in this regard. Its CNC engraving machines feature high-performance servo motors from renowned brands like YASKAWA, ensuring stable and efficient operation even during 800+ hours of continuous use. The laser sources, sourced from industry leaders such as MAX, Raycus, and IPG, provide consistent power output, enabling the machines to handle a wide range of metal materials (including stainless steel, aluminum alloy, and carbon steel) with precision cutting and engraving.

Key technical parameters further highlight this excellence: the positioning accuracy of Tianchen Laser’s CNC engraving machine reaches 0.05mm, with a repositioning accuracy of 0.03mm—figures that meet the strict requirements of high-end metal forming. Additionally, the machines support multiple graphic formats (AI, PLT, DXF, BMP, etc.), making it easy for customers to integrate them into existing production workflows. The modular countertop and partition dust removal system also enhance usability, reducing maintenance time and improving overall production efficiency. For industries like construction machinery, where large-format metal parts require high precision, Tianchen Laser’s CNC engraving machine delivers consistent results that exceed expectations.

Empowering Global Manufacturing: Tianchen Laser’s CNC Engraving Solutions

Tianchen Laser’s commitment to precision extends beyond the machine itself—it’s about providing end-to-end solutions that empower global manufacturers. The company’s CNC engraving machines are not off-the-shelf products; they are part of a comprehensive service that includes customized solutions tailored to specific industry needs. For example, in the automotive manufacturing sector, Tianchen Laser modifies its CNC engraving machines to handle the intricate patterns on tire molds and engine components, ensuring each part meets the strict safety standards of the automotive industry.

Quality assurance is another cornerstone: every CNC engraving machine undergoes rigorous testing (including precision calibration and durability checks) before leaving the factory, ensuring it meets the highest standards of performance. Fast delivery, a key advantage in today’s manufacturing environment, is made possible by Tianchen Laser’s efficient production and global logistics network—minimizing downtime for customers. By combining precision, customization, and reliability, Tianchen Laser’s CNC engraving machines are helping manufacturers in over 100 countries streamline processes, reduce costs, and stay ahead in a competitive market.

In the world of modern manufacturing, precision is the language of progress—and Tianchen Laser’s CNC engraving machine is a master of this language. With 29 years of experience, an intelligent manufacturing base, and a customer-centered approach, the company continues to redefine the potential of CNC engraving technology. For global manufacturers seeking to elevate their precision and efficiency, Tianchen Laser’s CNC engraving solutions are not just a choice—they are a strategic investment in the future of manufacturing.