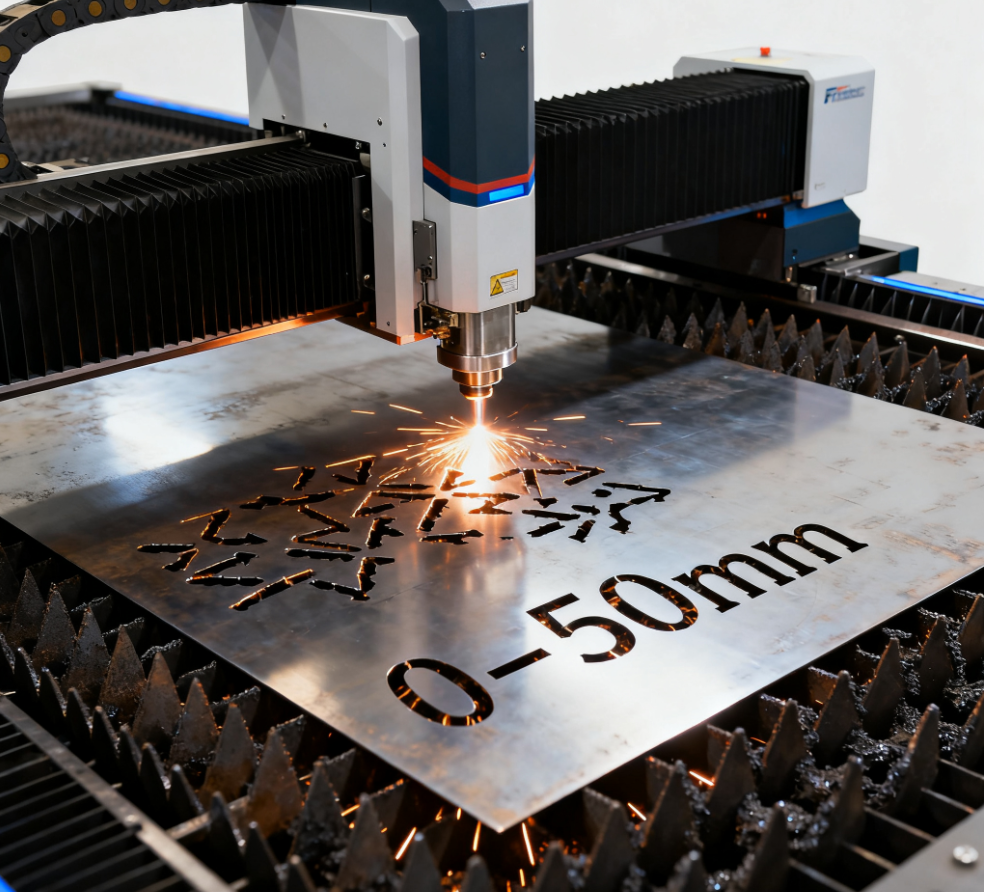

In the field of industrial manufacturing, metallic materials with a thickness of 1-50mm are among the most widely used ranges. From agricultural machinery parts and automotive components to heavy machinery frames and construction profiles, they cover almost all core scenarios of equipment manufacturing. However, metal processing in this thickness range has long faced the pain points of "difficulty balancing precision and efficiency" and "hard to reconcile cost and quality". Traditional plasma cutting tends to cause rough cuts and thermal deformation when processing thick metals above 20mm, while mechanical cutting struggles to meet the flexible needs when switching between thin and thick 1-50mm materials, with a high consumable loss rate. The emergence of fiber laser cutting machines, especially the series products launched by Tianchen Laser, provides an ideal solution for 1-50mm metallic material processing.

1. Core Pain Points of 1-50mm Metallic Material Processing and the Adaptability of Laser Cutting

The processing demand for 1-50mm metallic materials is characterized by "wide range and diverse scenarios": thin metal sheets as thin as 1mm require micron-level cutting precision, while thick carbon steel and stainless steel plates up to 50mm demand sufficient cutting power and stability. The shortcomings of traditional processing methods are particularly obvious in this range:

- Plasma cutting: Although it can cut thick metals above 30mm, high temperatures will cause oxidation and deformation of metal edges, requiring secondary grinding afterward, which increases process costs;

- Mechanical sawing: When processing thin metals of 1-10mm, the material is prone to warping due to excessive pressure, and the time cost of tool replacement will reduce overall efficiency;

- Water jet cutting: Although it can balance precision and thickness, the equipment has high operating costs and slow speed, making it difficult to adapt to mass production needs.

In contrast, fiber laser cutting technology, with its "cold cutting" feature, can effectively avoid thermal deformation, with a cutting precision of up to ±0.03mm, and a cutting speed 2-3 times that of traditional methods. More importantly, fiber laser cutting machines can flexibly adapt to metallic materials of different thicknesses from 1-50mm (such as carbon steel, stainless steel, aluminum alloy, etc.) by adjusting parameters, without frequent equipment or accessory replacement, perfectly solving the "range problem" of traditional processing. As an enterprise deeply engaged in the laser equipment field for 29 years, Tianchen Laser's products are more targeted in the adaptability of 1-50mm metal processing.

2. Tianchen Fiber Laser Cutting Machines: Technical Advantages for 1-50mm Metal Processing

Founded in 1995, Tianchen Laser has always focused on the R&D and manufacturing of intelligent laser equipment. Its core products have an annual production capacity of over 10,000 units, and its business covers more than 100 countries and regions worldwide. For 1-50mm metallic material processing, its series of fiber laser cutting machines have formed differentiated advantages through technological innovation:

- Full product series covering different thickness needs: Tianchen Laser has a complete product line including P Series, FB Series, TM Series, and FS Series, which can accurately match 1-50mm metal processing scenarios. For example, the NS3015 model, as a cost-effective option, is suitable for mass processing of 1-20mm thin to medium metals, balancing quality and cost; the PM3015 model is equipped with advanced laser cutting technology, which enhances the cutting efficiency of 20-50mm thick metals and can increase the cutting speed of 50mm carbon steel to 1.5 times that of traditional equipment; the FB12525 large-format laser cutting machine can process large 1-50mm metal workpieces, meeting the large-scale processing needs of the heavy machinery and construction industries.

- Core technologies ensuring precision and stability: Tianchen fiber laser cutting machines are equipped with a servo follow-up system and front clamp override function. The former can real-time adapt to the cutting height of 1-50mm metallic materials with different thicknesses, avoiding cut deviations caused by material thickness fluctuations; the latter can reduce material waste, especially when processing 1-5mm thin metal coils, increasing material utilization by more than 10%. In addition, the equipment adopts original imported core accessories, combined with high-precision testing equipment such as laser interferometers and ball bars, ensuring the long-term stable cutting precision of each machine.

- Efficient delivery and customization capabilities: Relying on an intelligent manufacturing base, Tianchen Laser can realize the rapid production and delivery of 1-50mm metal processing equipment, shortening the delivery cycle of conventional models to 7-15 days; at the same time, for special industries (such as the processing of 10-30mm special alloys for aerospace parts), it can provide customized solutions, adjusting parameters such as laser power and cutting path to meet personalized needs.

3. Application Practices of Tianchen Fiber Laser Cutting Machines in 1-50mm Metal Processing Across Industries

With its adaptability to 1-50mm metallic materials, Tianchen fiber laser cutting machines have been widely used in four core industries to solve practical processing problems:

- Agricultural machinery industry: The metal frames and seeder parts of agricultural machinery mostly use 10-30mm carbon steel. Tianchen's NS3015 fiber laser cutting machine can achieve high-precision cutting, and the cuts do not require secondary processing, directly meeting welding needs, increasing production efficiency by 30%;

- Automotive manufacturing industry: Automotive chassis components and exhaust pipes use 5-25mm stainless steel and aluminum alloy. The high-speed cutting capability of Tianchen's PM3015 model can realize mass processing of more than 500 pieces per day, with smooth cutting edges, reducing subsequent polishing costs;

- Heavy machinery industry: The booms of excavators and cranes are mostly 30-50mm thick steel plates. Tianchen's FB12525 large-format fiber laser cutting machine can complete the cutting of large workpieces at one time, avoiding precision errors caused by segmental processing, and increasing the qualification rate to 99.5%;

- Construction industry: Construction steel structures and curtain wall keels use 15-40mm metal profiles. Tianchen's fiber laser cutting machine can realize complex shape cutting, adapting to the personalized design of modern buildings, while meeting structural requirements such as wind pressure resistance and load-bearing.

4. Core Reasons to Choose Tianchen Fiber Laser Cutting Machines for 1-50mm Metallic Materials

For enterprises needing to process 1-50mm metallic materials, choosing Tianchen fiber laser cutting machines essentially means choosing a "stable, efficient, and low-cost" processing solution:

- Quality assurance: Tianchen Laser is a national high-tech enterprise with more than 20 software copyrights and patents. Its products have passed the ISO9001 quality management system certification and have won provincial and national honors for many years. Its quality reputation has been verified by the market for 29 years;

- Global service network: With business covering more than 100 countries and regions, Tianchen Laser has after-sales service centers in major markets, providing 24-hour technical support. Whether it is equipment installation and commissioning or 1-50mm processing parameter optimization, it can respond quickly;

- Cost advantage: Through large-scale production and independent R&D, Tianchen Laser reduces equipment procurement costs. At the same time, the energy consumption of laser cutting is only 1/3 of that of plasma cutting, which can save a lot of operating costs in long-term use, especially suitable for mass processing scenarios of 1-50mm metals.

In conclusion, in the field of 1-50mm metallic material processing, Tianchen fiber laser cutting machines have become the ideal choice for enterprises to improve processing efficiency and reduce costs with the advantages of "full series coverage, high precision stability, and multi-industry adaptability". Whether it is mass production for small and medium-sized enterprises or customized needs for large enterprises, Tianchen Laser can provide suitable solutions to help upgrade industrial manufacturing.

Table of Contents

- 1. Core Pain Points of 1-50mm Metallic Material Processing and the Adaptability of Laser Cutting

- 2. Tianchen Fiber Laser Cutting Machines: Technical Advantages for 1-50mm Metal Processing

- 3. Application Practices of Tianchen Fiber Laser Cutting Machines in 1-50mm Metal Processing Across Industries

- 4. Core Reasons to Choose Tianchen Fiber Laser Cutting Machines for 1-50mm Metallic Materials