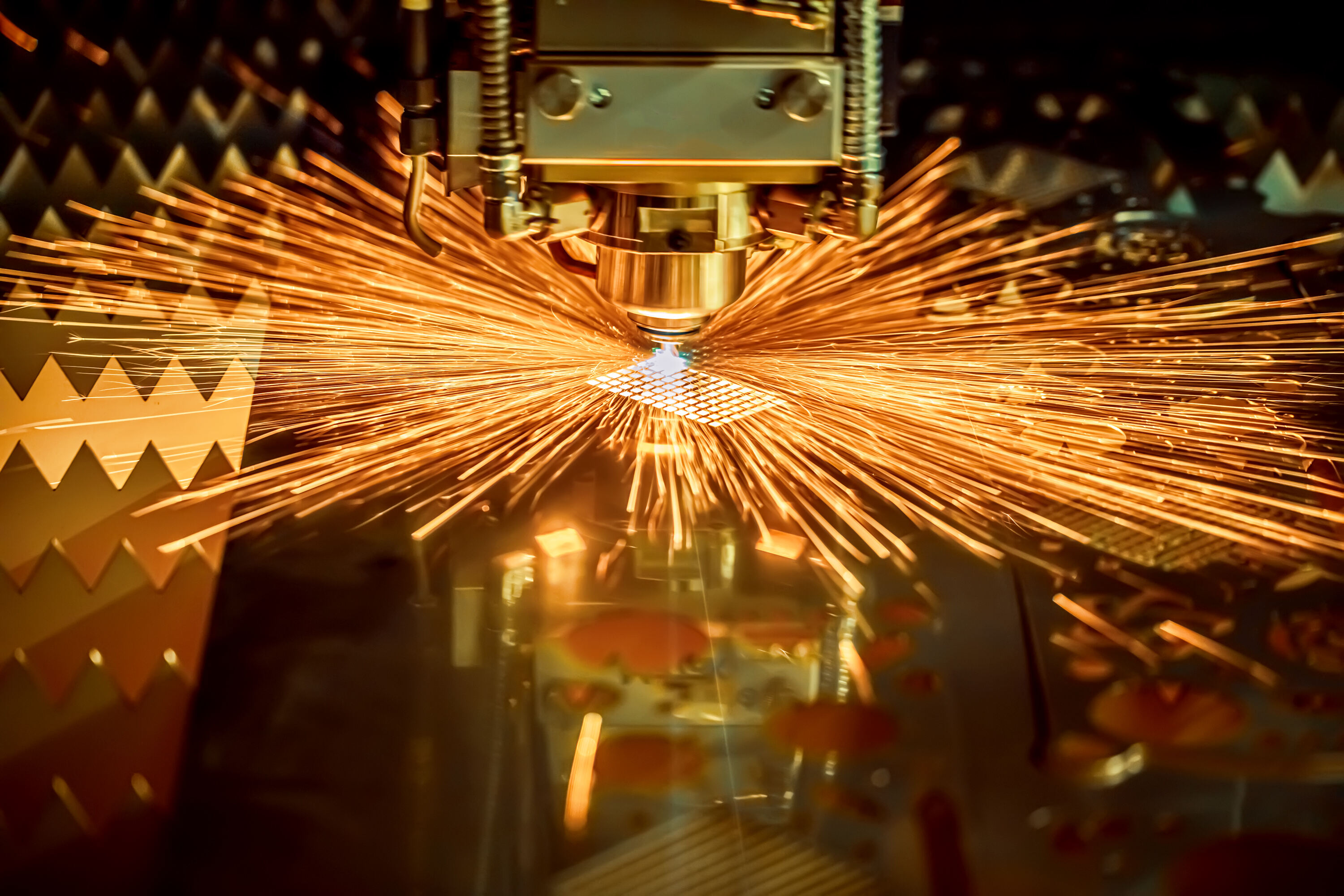

In the modern metal processing industry, metal laser cutting technology has evolved from an "auxiliary tool" to a "core engine", completely addressing the pain points of low efficiency and poor precision in traditional cutting processes. Founded in 1995, Tianchen Laser is a high-tech enterprise with 29 years of experience in the R&D, production, and sales of intelligent metal forming equipment. Boasting an intelligent manufacturing base with an annual production capacity of over 10,000 units, a business network covering more than 100 countries and regions, and a diverse range of metal laser cutting machines (such as the P Series, FB Series, and PM Series), Tianchen Laser has become a trusted solution provider for global customers. This article will analyze the core advantages of metal laser cutting technology from five key dimensions, and how Tianchen Laser translates these advantages into practical production value.

1. Micron-Level Precision: Redefining Metal Cutting Quality Standards

The core competitiveness of metal laser cutting lies in its unparalleled precision—one of the key highlights of Tianchen Laser’s equipment. The diameter of the laser beam can be refined to less than 0.1mm, and with the support of a CNC system, it achieves a micron-level positioning accuracy of ±0.05mm, far exceeding the error range of ±0.2mm to ±0.5mm of traditional plasma cutting. Take Tianchen Laser’s PM3015 model as an example: its advanced laser cutting technology controls the cutting edge roughness to Ra ≤ 3.2μm, resulting in smooth and flat cuts that meet precision assembly requirements without secondary grinding. This makes it particularly suitable for industries with strict precision demands, such as automotive manufacturing and aerospace.

Traditional mechanical cutting often causes stress deformation due to tool contact, but the "non-contact processing" feature of metal laser cutting completely avoids this issue. Tianchen Laser integrates servo follow-up technology into its P Series equipment, ensuring no physical contact between the cutting head and the workpiece. Even when processing thin plates or brittle materials (such as stainless steel and aluminum alloys), the integrity of the material is maintained—this is a key reason why its products are widely popular in the agricultural machinery and heavy machinery industries.

2. High Efficiency & Flexibility: Adapting to Diverse Working Conditions

Efficiency is a core indicator for enterprises to reduce costs and improve benefits, and metal laser cutting stands out significantly in this dimension. Compared with flame cutting, which takes 10 minutes to cut a 20mm-thick carbon steel plate, Tianchen Laser’s equipment can complete the same task in just 1 minute, with a maximum cutting speed of 20m/min—more than three times that of traditional processes. Among them, Tianchen Laser’s P Series is known as the "King of Efficiency Among Peers" for its ability to quickly process complex patterns and small holes, while the FB Series large-format laser cutting machines (such as the FB12525) are suitable for large-scale industrial projects, balancing power and precision to meet both mass production and customized processing needs.

To further enhance efficiency, Tianchen Laser’s equipment supports seamless integration with automated loading and unloading systems and intelligent nesting software, enabling 24/7 continuous operation. Relying on the company’s "fast delivery" service commitment, customers can start their production lines without long waits—a crucial advantage for clients in the construction machinery and electronic equipment industries with tight project schedules.

3. Wide Material Compatibility: Covering Multi-Industry Needs

The "versatility" of metal laser cutting is reflected in its broad material adaptability—which aligns with Tianchen Laser’s concept of "providing customized solutions for global customers". Whether it is common metals such as carbon steel, stainless steel, and aluminum alloy, or special materials like copper and titanium alloy, Tianchen Laser’s equipment can cut them efficiently, covering a thickness range of 0.1mm to 30mm (different models adapt to different thicknesses).

To meet diverse customer needs, Tianchen Laser offers differentiated products: the NS3015, as a cost-effective metal laser cutting machine, meets the high-quality metal processing needs of small and medium-sized enterprises with its excellent cost-performance ratio; the M230, with its robust structure and stable cutting mechanism, is a "reliable choice" in the metal processing field. This diversified layout allows Tianchen Laser’s business to penetrate multiple scenarios, including agricultural machinery manufacturing, auto parts, and the construction industry, truly realizing "one machine, multiple uses".

4. Intelligent Automation: Driving Cost Reduction & Efficiency Improvement

Against the backdrop of Industry 4.0, "intelligence" has become a core upgrade direction for metal laser cutting, and Tianchen Laser has long laid out its strategy in this field. The company’s intelligent manufacturing base not only achieves an annual production capacity of over 10,000 units for its main products but also integrates technologies such as AI visual positioning and real-time fault early warning into its equipment. For example, some models are equipped with an automatic focus function that reduces piercing time by 80%; intelligent nesting software can improve material utilization by 5% to 15%, avoiding material waste in traditional processes.

Automation also significantly reduces labor costs: Tianchen Laser’s equipment supports unattended operation, minimizing human intervention while keeping the defect rate extremely low. After a mechanical manufacturing customer introduced Tianchen’s equipment, the cutting qualification rate increased from 90% to 99%, saving an average of 50,000 yuan in monthly labor costs—fully verifying the practical value of intelligent technology. In addition, Tianchen Laser’s "customized solution" service optimizes equipment parameters according to the characteristics of customers’ production lines, further amplifying the effects of cost reduction and efficiency improvement.

5. Green & Sustainable Production: Aligning with Global Development Trends

As environmental protection requirements become increasingly strict, the "green attributes" of metal laser cutting have gradually become an important consideration for enterprises. Unlike traditional cutting processes that produce smoke, noise, and pollution, Tianchen Laser’s equipment uses inert gas-assisted cutting to reduce harmful emissions; at the same time, the absence of mold consumption not only lowers upfront investment costs but also avoids environmental pressure caused by mold waste.

From an energy consumption perspective, Tianchen Laser’s equipment has a high photoelectric conversion rate, saving more than 30% energy compared to traditional cutting. Long-term use can significantly reduce energy expenditure. This dual advantage of "environmental protection + economy" aligns with the global trend of the manufacturing industry transitioning to "green manufacturing"—and it is also an important reason why Tianchen Laser’s business covers more than 100 countries and regions. Whether it is the environmental regulations of European and American markets or the cost needs of emerging markets, Tianchen Laser can provide suitable solutions.

In summary, the five core advantages of metal laser cutting—precision, efficiency, compatibility, intelligence, and environmental protection—are driving the metal processing industry toward a "high-precision, high-efficiency, and high-tech" transformation. With 29 years of technical accumulation, a diversified product portfolio, and a global service network, Tianchen Laser translates these advantages into tangible value for customers, becoming a leader in the metal laser cutting field. In the future, as Tianchen Laser continues to innovate in technologies such as extra-thick plate cutting and AI path optimization, it will further lead the industry’s development and create more possibilities for global customers.

Table of Contents

- 1. Micron-Level Precision: Redefining Metal Cutting Quality Standards

- 2. High Efficiency & Flexibility: Adapting to Diverse Working Conditions

- 3. Wide Material Compatibility: Covering Multi-Industry Needs

- 4. Intelligent Automation: Driving Cost Reduction & Efficiency Improvement

- 5. Green & Sustainable Production: Aligning with Global Development Trends