In the modern manufacturing landscape, metal processing efficiency and storage flexibility have become core competitiveness for enterprises. As a high-tech enterprise founded in 1995, Tianchen Laser has been committed to providing global customers with metal forming and automated production line solutions for 29 years. With the upgrading of laser cutting workshops in various industries, the integration of high-efficiency laser cutting technology and intelligent metal storage towers has become an inevitable trend, and Tianchen Laser is leading this transformation with its professional strength.

The Core Demand of Laser Cutting Workshop Upgrade: Efficiency and Flexibility

Traditional laser cutting workshops often face pain points such as low material utilization, cumbersome storage management, and disconnection between cutting and storage processes. In the context of increasing production costs and rising market demand for precision, upgrading to achieve high efficiency and flexibility has become a top priority for enterprises. Metal storage towers, as an important part of the workshop logistics system, are not only responsible for the storage of raw materials and finished products but also directly affect the continuity and stability of the laser cutting process.

Tianchen Laser, with its customer-centered approach, deeply understands the actual needs of various industries. Its intelligent manufacturing base, with an annual production capacity of over 10,000 units, provides a solid foundation for the R&D and production of matching storage solutions. The company's business covers more than 100 countries and regions, and through in-depth cooperation with customers worldwide, it has summarized rich experience in workshop upgrading, especially in the integration of laser cutting and metal storage towers.

Tianchen Laser's Technical Support: Driving the Evolution of Metal Storage Towers

The high-efficiency and flexible development of metal storage towers cannot be separated from the support of advanced laser cutting technology. Tianchen Laser's full range of laser cutting machines, such as the cost-effective NS3015, reliable M230, and large-format FB12525, have laid a solid technical foundation for the upgrading of metal storage towers. These laser cutting machines feature high precision, high efficiency, and stable performance, ensuring that the processed metal components of storage towers meet strict quality standards.

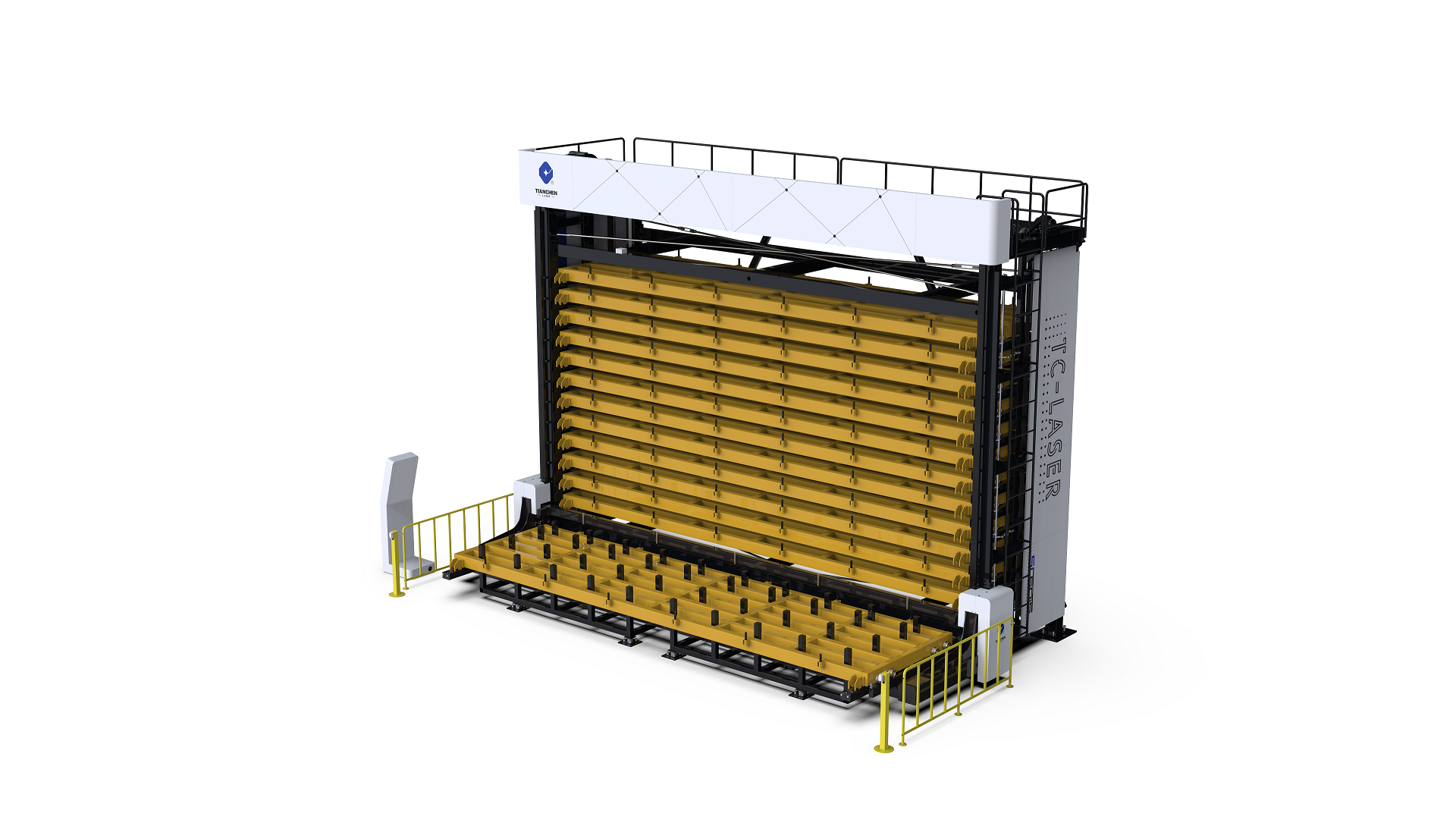

In addition, Tianchen Laser has obtained more than 20 software copyrights and patents since 2019, continuously innovating in intelligent control and automated connection technology. The automated tower storage equipment independently developed by the company can be perfectly matched with various laser cutting machines, realizing seamless connection between material unloading, storage, and retrieval. This integration not only reduces manual intervention, improves storage efficiency but also enhances the flexibility of the workshop, enabling enterprises to quickly respond to changes in production orders.

Application Practice: Metal Storage Towers Empowering Diversified Industries

Tianchen Laser's laser cutting and storage integrated solutions have been widely applied in industries such as agricultural machinery, heavy machinery, automotive manufacturing, and construction. In the automotive manufacturing industry, the demand for metal components is large and diverse, and the intelligent metal storage towers matched with Tianchen's laser cutting machines can classify and store different types of auto parts, improving the efficiency of the production line; in the construction industry, large-format laser cutting machines such as FB12525 cooperate with high-capacity storage towers to meet the storage needs of large-scale metal structural parts, ensuring the smooth progress of construction projects.

With its quality-oriented and service-oriented philosophy, Tianchen Laser provides customized solutions for different industry customers. Whether it is a small workshop or a large-scale manufacturing enterprise, it can obtain suitable laser cutting and storage integration plans. This personalized service has won wide recognition from customers around the world and has also made Tianchen Laser a trusted partner in the global laser cutting workshop upgrade field.

The Future Trend: Intelligent Integration of Laser Cutting and Storage

As the manufacturing industry moves towards intelligence and automation, the integration of laser cutting and metal storage towers will become more in-depth. Tianchen Laser will continue to uphold the principle of focusing on quality and service, relying on its professional R&D team to continuously innovate in technology. In the future, metal storage towers will be more intelligent, with functions such as real-time inventory monitoring, automatic inventory replenishment, and intelligent scheduling, closely linking with laser cutting machines to form a fully automated production ecosystem.

For 29 years, Tianchen Laser has grown rapidly in the laser industry, and its business has spread to more than 100 countries and regions around the world. In the wave of laser cutting workshop upgrades, the company will continue to use its rich experience, advanced technology, and high-quality products to help global customers achieve high-efficiency and flexible development of metal storage towers, creating greater value for the sustainable development of enterprises.