In the dynamic field of metal fabrication, laser cutting machines have become the backbone of efficient production. However, sheet metal storage has long been a stubborn pain point for manufacturers worldwide. Sheet pile-up not only devours valuable workshop space but also disrupts production workflows, reduces operational efficiency, and even poses safety hazards. As a high-tech enterprise specializing in laser technology since 1995, Tianchen Laser deeply understands the challenges faced by manufacturers. Leveraging its 29 years of industry experience and global insights, the company has launched a targeted space optimization solution — the sheet metal storage tower, which perfectly complements its full range of laser cutting machines to redefine intelligent storage in metal processing.

1. The Pain Points of Traditional Sheet Metal Storage in Laser Cutting Production

Traditional sheet metal storage methods, such as horizontal stacking and scattered placement, have obvious drawbacks that hinder production development. Firstly, horizontal storage occupies a large amount of floor space. For manufacturers with limited workshop areas, the waste of space directly restricts the expansion of production scale. Secondly, managing different specifications and materials of sheet metal is cumbersome. Manual sorting and retrieval are time-consuming and error-prone, leading to delays in the laser cutting process and reduced production continuity. Thirdly, stacked sheets are prone to deformation, corrosion, or surface scratches, affecting the quality of subsequent cutting products. Moreover, manual handling of heavy sheets increases labor intensity and the risk of workplace accidents. With the continuous growth of global manufacturing demand, these pain points have become increasingly prominent, making space optimization and efficient storage an urgent need for enterprises seeking to enhance competitiveness.

2. Tianchen Laser’s Sheet Metal Storage Tower: Core Advantages for Space Optimization

Tianchen Laser’s sheet metal storage tower is developed based on the actual needs of laser cutting production, integrating space-saving design, intelligent control, and high compatibility. Its core advantages are remarkable:

- Vertical Space Maximization: Adopting a vertical storage structure, the tower makes full use of the vertical space of the workshop, reducing floor space by more than 60% compared to traditional horizontal storage. This breakthrough allows manufacturers to expand storage capacity without increasing workshop area, effectively solving the problem of space shortage.

- Intelligent Automated Operation: Equipped with an advanced intelligent control system, the storage tower realizes automatic loading, unloading, sorting, and retrieval of sheet metal. It can seamlessly connect with laser cutting machines, achieving a fully automated material flow from storage to cutting. This not only eliminates manual intervention but also improves operational efficiency by 30% or more.

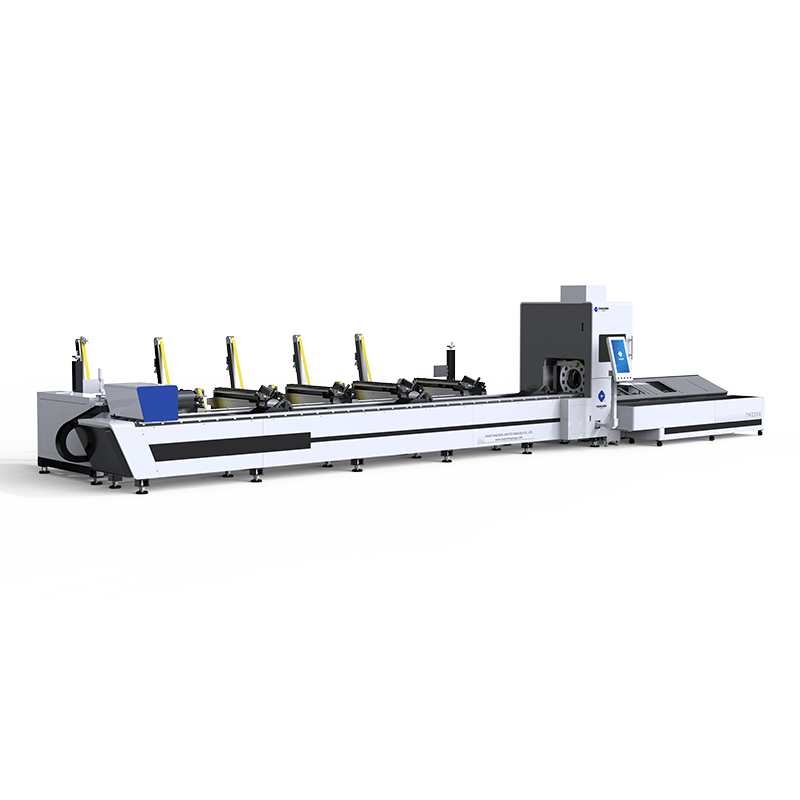

- Strong Compatibility and Stability: The storage tower is tailored to match Tianchen Laser’s diverse laser cutting machine series, including the cost-effective NS3015, reliable M230, large-format FB12525, and advanced PM3015 models. Made of high-quality materials and precision-manufactured at the intelligent manufacturing base with an annual production capacity of over 10,000 units, it ensures stable operation even in long-term high-intensity production environments.

- Customized Design: Adhering to a customer-centered approach, Tianchen Laser provides customized storage tower solutions according to the specific needs of customers, such as sheet metal size, storage capacity, and workshop layout. This flexibility enables the solution to adapt to the diverse requirements of different industries and enterprises.

3. Integration with Laser Cutting Equipment: Enhancing Production Efficiency

The sheet metal storage tower is not an independent equipment but an important part of Tianchen Laser’s one-stop laser cutting solution. Its seamless integration with laser cutting machines creates a closed-loop automated production line, bringing multiple efficiency improvements:

- Continuous Production Guarantee: The automated material supply of the storage tower ensures that the laser cutting machine never stops due to material shortage, realizing 24/7 continuous operation and greatly improving equipment utilization.

- Precision Synergy: With servo follow-up and precise positioning technologies, the storage tower can accurately deliver the required sheet metal to the cutting platform, matching the high-precision cutting performance of Tianchen’s laser cutting machines. This synergy reduces material waste caused by positioning errors and improves product quality consistency.

- Simplified Production Management: The integrated intelligent system allows centralized monitoring and management of both the storage tower and laser cutting machine. Production data such as material inventory, cutting progress, and equipment status can be real-time tracked, helping enterprises optimize production scheduling and reduce management costs.

4. Global Application Cases: Proving Reliability Across Industries

Tianchen Laser’s sheet metal storage tower, together with its laser cutting machines, has been widely applied in more than 100 countries and regions, serving industries such as agricultural machinery, automotive manufacturing, heavy machinery, and construction.

In the automotive manufacturing industry, a European manufacturer adopted Tianchen’s integrated solution and successfully reduced its workshop space occupation by 55% while increasing production efficiency by 32%. The storage tower’s ability to handle various sheet metal specifications perfectly meets the diverse needs of auto parts production. In the heavy machinery sector, a domestic enterprise used the large-format FB12525 laser cutting machine paired with a customized storage tower, solving the long-standing problem of storing and handling large and heavy metal sheets, and shortening the production cycle by 28%. These successful cases fully demonstrate the reliability and effectiveness of Tianchen’s space optimization solution in different industrial scenarios.

5. Why Choose Tianchen Laser for Your Storage & Cutting Solutions

Choosing Tianchen Laser means choosing a professional, reliable, and customer-centric partner. Since its establishment in 1995, Tianchen Laser has been committed to technological innovation and quality improvement, holding over 20 software copyrights and patents. Its intelligent manufacturing base ensures strict quality control throughout the production process, and the fast delivery service guarantees that customers receive equipment on time.

Adhering to the principle of focusing on quality and service, Tianchen Laser provides comprehensive pre-sales consultation, in-sales customization, and after-sales maintenance services. Whether you are a small and medium-sized enterprise looking for cost-effective solutions or a large industrial group with large-scale production needs, Tianchen Laser can tailor exclusive storage and cutting integrated solutions to help you achieve space optimization, efficiency improvement, and cost reduction.

In the era of intelligent manufacturing, space and efficiency are the core competitiveness of enterprises. Tianchen Laser’s sheet metal storage tower, with its outstanding space optimization capabilities and seamless integration with laser cutting machines, helps manufacturers say goodbye to sheet pile-up and embrace a more efficient, intelligent, and cost-effective production mode. With Tianchen Laser as your partner, you can gain a competitive edge in the global market and achieve sustainable development.

Table of Contents

- 1. The Pain Points of Traditional Sheet Metal Storage in Laser Cutting Production

- 2. Tianchen Laser’s Sheet Metal Storage Tower: Core Advantages for Space Optimization

- 3. Integration with Laser Cutting Equipment: Enhancing Production Efficiency

- 4. Global Application Cases: Proving Reliability Across Industries

- 5. Why Choose Tianchen Laser for Your Storage & Cutting Solutions