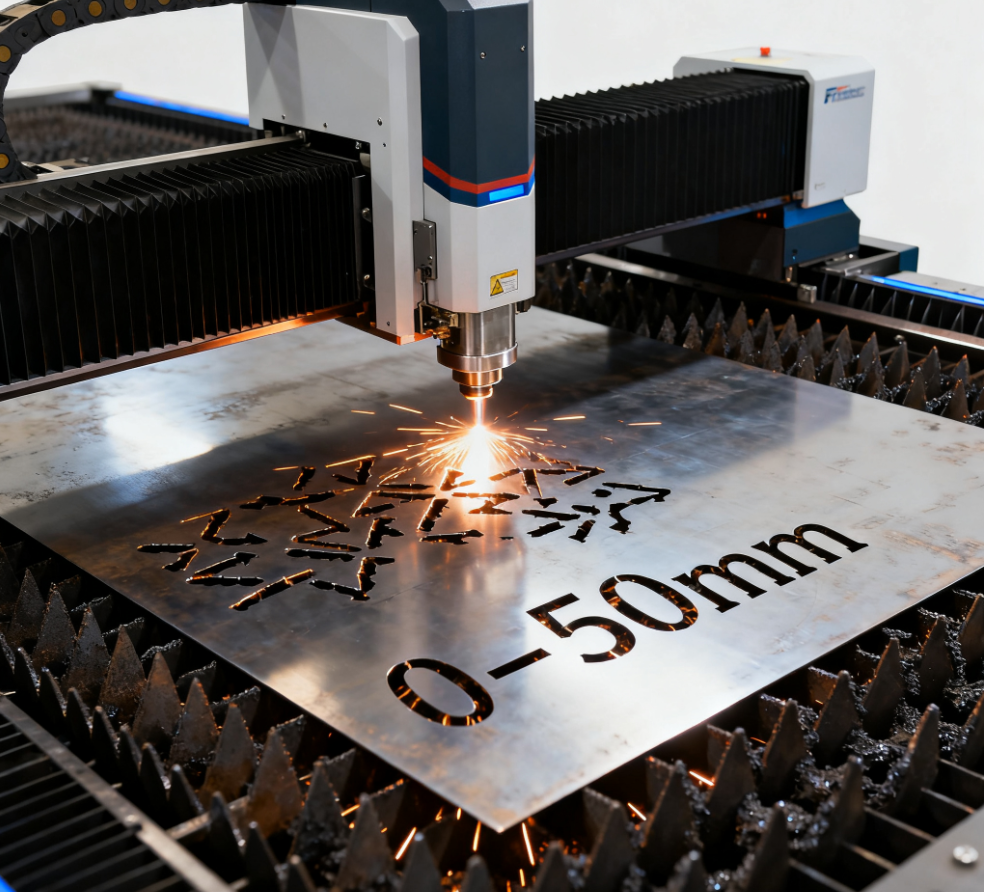

En el campo de la fabricación industrial, los materiales metálicos con un espesor de entre 1 y 50 mm se encuentran entre los rangos más utilizados. Desde piezas de maquinaria agrícola y componentes automotrices hasta bastidores de maquinaria pesada y perfiles de construcción, abarcan prácticamente todos los escenarios clave de la fabricación de equipos. Sin embargo, el procesamiento de metales en este rango de espesor ha enfrentado durante mucho tiempo los problemas de "dificultad para equilibrar precisión y eficiencia" y "dificultad para conciliar costo y calidad". El corte por plasma tradicional tiende a provocar cortes rugosos y deformaciones térmicas al procesar metales gruesos superiores a 20 mm, mientras que el corte mecánico tiene dificultades para satisfacer las necesidades flexibles al cambiar entre materiales delgados y gruesos de 1-50 mm, con una alta tasa de pérdida de consumibles. La aparición de máquinas de corte por láser de fibra, especialmente las series de productos lanzadas por Tianchen Laser, proporciona una solución ideal para el procesamiento de materiales metálicos de 1-50 mm.

1. Puntos clave de dolor en el procesamiento de materiales metálicos de 1-50 mm y la adaptabilidad del corte por láser

La demanda de procesamiento para materiales metálicos de 1-50 mm se caracteriza por ser "amplia y con diversos escenarios": las láminas metálicas delgadas de tan solo 1 mm requieren una precisión de corte al nivel de micrones, mientras que las placas gruesas de acero al carbono y acero inoxidable de hasta 50 mm exigen suficiente potencia y estabilidad de corte. Las limitaciones de los métodos tradicionales de procesamiento son particularmente evidentes en este rango:

- Corte por plasma: Aunque puede cortar metales gruesos superiores a 30 mm, las altas temperaturas provocan oxidación y deformación en los bordes metálicos, lo que requiere un rectificado secundario posterior, aumentando así los costos del proceso;

- Serrado mecánico: Al procesar metales delgados de 1-10 mm, el material tiende a deformarse debido a la presión excesiva, y el costo en tiempo del reemplazo de herramientas reduce la eficiencia general;

- Corte por chorro de agua: aunque puede equilibrar precisión y espesor, el equipo tiene altos costos operativos y velocidad lenta, lo que dificulta adaptarse a las necesidades de producción en masa.

En contraste, la tecnología de corte por láser de fibra, con su característica de "corte frío", puede evitar eficazmente la deformación térmica, con una precisión de corte de hasta ±0,03 mm y una velocidad de corte 2-3 veces mayor que los métodos tradicionales. Más importante aún, las máquinas de corte por láser de fibra pueden adaptarse flexiblemente a materiales metálicos de diferentes espesores, desde 1 hasta 50 mm (como acero al carbono, acero inoxidable, aleación de aluminio, etc.), ajustando los parámetros, sin necesidad de reemplazar frecuentemente el equipo o accesorios, resolviendo perfectamente el "problema de rango" del procesamiento tradicional. Como empresa profundamente especializada en el campo de equipos láser durante 29 años, los productos de Tianchen Laser son más específicos en cuanto a la adaptabilidad al procesamiento de metales de 1-50 mm.

2. Máquinas de Corte por Láser de Fibra Tianchen: Ventajas Técnicas para el Procesamiento de Metales de 1-50 mm

Fundada en 1995, Tianchen Laser siempre se ha centrado en la I+D y fabricación de equipos láser inteligentes. Sus productos principales tienen una capacidad de producción anual de más de 10.000 unidades, y su negocio abarca más de 100 países y regiones en todo el mundo. Para el procesamiento de materiales metálicos de 1-50 mm, su serie de máquinas de corte por láser de fibra ha desarrollado ventajas diferenciadas mediante la innovación tecnológica:

- Serie completa de productos que cubre diferentes necesidades de grosor : Tianchen Laser cuenta con una línea completa de productos que incluye las series P, FB, TM y FS, las cuales pueden adaptarse exactamente a escenarios de procesamiento de metales de 1-50 mm. Por ejemplo, el modelo NS3015, como opción económica, es adecuado para el procesamiento en masa de metales delgados a medianos de 1-20 mm, equilibrando calidad y costo; el modelo PM3015 está equipado con tecnología avanzada de corte por láser, que mejora la eficiencia en el corte de metales gruesos de 20-50 mm y puede aumentar la velocidad de corte del acero al carbono de 50 mm hasta 1,5 veces la de los equipos tradicionales; la máquina de corte por láser de gran formato FB12525 puede procesar piezas metálicas grandes de 1-50 mm, satisfaciendo las necesidades de procesamiento a gran escala de las industrias de maquinaria pesada y construcción.

- Tecnologías clave que garantizan precisión y estabilidad : Las máquinas de corte por láser de fibra Tianchen están equipadas con un sistema servo de seguimiento y la función de sobrepaso del sujetador frontal. El primero puede adaptarse en tiempo real a la altura de corte de materiales metálicos de 1-50 mm con diferentes espesores, evitando desviaciones de corte causadas por fluctuaciones en el grosor del material; la segunda puede reducir el desperdicio de material, especialmente al procesar bobinas de metal delgado de 1-5 mm, aumentando la utilización del material en más del 10 %. Además, el equipo adopta accesorios centrales importados originales, combinados con equipos de prueba de alta precisión como interferómetros láser y barras de bolas, garantizando la precisión estable de corte a largo plazo de cada máquina.

- Entrega eficiente y capacidades de personalización : Aprovechándose de una base de fabricación inteligente, Tianchen Laser puede realizar la producción y entrega rápidas de equipos para el procesamiento de metales de 1-50 mm, acortando el ciclo de entrega de los modelos convencionales a 7-15 días; al mismo tiempo, para industrias especiales (como el procesamiento de aleaciones especiales de 10-30 mm para piezas aeroespaciales), puede ofrecer soluciones personalizadas, ajustando parámetros como la potencia del láser y la trayectoria de corte para satisfacer necesidades personalizadas.

3. Aplicaciones prácticas de las máquinas de corte por láser de fibra Tianchen en el procesamiento de metales de 1-50 mm en diversos sectores

Gracias a su adaptabilidad a materiales metálicos de 1-50 mm, las máquinas de corte por láser de fibra Tianchen se han utilizado ampliamente en cuatro industrias clave para resolver problemas prácticos de procesamiento:

- Industria de maquinaria agrícola : Los marcos metálicos y las piezas sembradoras de maquinaria agrícola utilizan principalmente acero al carbono de 10-30 mm. La máquina de corte por láser de fibra NS3015 de Tianchen puede lograr un corte de alta precisión, y los cortes no requieren procesamiento secundario, satisfaciendo directamente las necesidades de soldadura, aumentando la eficiencia de producción en un 30 %;

- Industria de fabricación automotriz : Los componentes del chasis automotriz y los tubos de escape utilizan acero inoxidable y aleación de aluminio de 5-25 mm. La capacidad de corte a alta velocidad del modelo PM3015 de Tianchen puede realizar procesamiento masivo de más de 500 piezas por día, con bordes de corte lisos, reduciendo los costos posteriores de pulido;

- Industria de maquinaria pesada : Las plumas de excavadoras y grúas son principalmente placas de acero de 30-50 mm de espesor. La máquina de corte por láser de fibra de gran formato FB12525 de Tianchen puede completar el corte de piezas grandes de una sola vez, evitando errores de precisión causados por el procesamiento segmentado y aumentando la tasa de conformidad hasta el 99,5 %;

- Industria de la Construcción : Las estructuras de acero para construcción y los perfiles de cerramiento utilizan perfiles metálicos de 15-40 mm. La máquina de corte por láser de fibra de Tianchen puede realizar cortes de formas complejas, adaptándose al diseño personalizado de edificios modernos, al mismo tiempo que cumple con requisitos estructurales como resistencia a la presión del viento y capacidad de carga.

4. Razones principales para elegir las máquinas de corte por láser de fibra Tianchen para materiales metálicos de 1-50 mm

Para las empresas que necesitan procesar materiales metálicos de 1-50 mm, elegir las máquinas de corte por láser de fibra Tianchen significa esencialmente elegir una solución de procesamiento "estable, eficiente y de bajo costo":

- Garantía de calidad : Tianchen Laser es una empresa nacional de alta tecnología con más de 20 derechos de software y patentes. Sus productos han pasado la certificación del sistema de gestión de calidad ISO9001 y han recibido reconocimientos provinciales y nacionales durante muchos años. Su reputación de calidad ha sido verificada por el mercado durante 29 años;

- Red de servicios globales : Con negocios en más de 100 países y regiones, Tianchen Laser cuenta con centros de servicio posventa en los principales mercados, ofreciendo soporte técnico las 24 horas. Ya sea para la instalación y puesta en marcha del equipo o para la optimización de parámetros de procesamiento de 1-50 mm, puede responder rápidamente;

- Ventaja de costo : A través de la producción a gran escala y la I+D independiente, Tianchen Laser reduce los costos de adquisición de equipos. Al mismo tiempo, el consumo energético del corte láser es solo un tercio del corte por plasma, lo que permite ahorrar significativamente en costos operativos a largo plazo, especialmente adecuado para escenarios de procesamiento masivo de metales de 1-50 mm.

En conclusión, en el campo del procesamiento de materiales metálicos de 1-50 mm, las máquinas de corte por láser de fibra Tianchen se han convertido en la opción ideal para que las empresas mejoren la eficiencia de procesamiento y reduzcan costos, gracias a sus ventajas de "cobertura completa de la gama, alta precisión y estabilidad, y adaptabilidad a múltiples industrias". Ya sea producción en masa para pequeñas y medianas empresas o necesidades personalizadas para grandes empresas, Tianchen Laser puede proporcionar soluciones adecuadas para ayudar a impulsar la modernización de la fabricación industrial.

Tabla de Contenido

- 1. Puntos clave de dolor en el procesamiento de materiales metálicos de 1-50 mm y la adaptabilidad del corte por láser

- 2. Máquinas de Corte por Láser de Fibra Tianchen: Ventajas Técnicas para el Procesamiento de Metales de 1-50 mm

- 3. Aplicaciones prácticas de las máquinas de corte por láser de fibra Tianchen en el procesamiento de metales de 1-50 mm en diversos sectores

- 4. Razones principales para elegir las máquinas de corte por láser de fibra Tianchen para materiales metálicos de 1-50 mm