The heavy machinery sector stands as the backbone of global industrial development, encompassing industries such as construction machinery, agricultural machinery, and heavy equipment manufacturing. In these fields, metal cutting is a core process that directly impacts product quality, production efficiency, and operational reliability. As heavy machinery components often feature large sizes, thick materials, and complex structures, the requirements for metal cutting solutions are extremely stringent—demanding high precision, high efficiency, durability, and adaptability to diverse production scenarios. For over 29 years, Tianchen Laser has been a trusted partner in the heavy machinery industry, delivering tailored metal cutting solutions that address these critical needs.

Key Requirements of Metal Cutting in Heavy Machinery Manufacturing

Heavy machinery manufacturing poses unique challenges for metal cutting. Firstly, the components—such as frames, gears, and structural parts—are typically made of thick steel plates or high-strength alloys, requiring cutting equipment to handle materials with exceptional power and stability. Secondly, precision is non-negotiable: even minor deviations in cutting dimensions can lead to assembly failures or safety hazards, making high-precision cutting a fundamental requirement. Thirdly, mass production in the heavy machinery sector demands efficient cutting processes to meet tight production schedules without compromising quality. Additionally, environmental friendliness and operational safety are increasingly important, as manufacturers seek solutions that reduce energy consumption and minimize workplace risks. These requirements call for metal cutting solutions that combine advanced technology, robust performance, and intelligent design.

Tianchen Laser’s Tailored Metal Cutting Solutions for Heavy Machinery

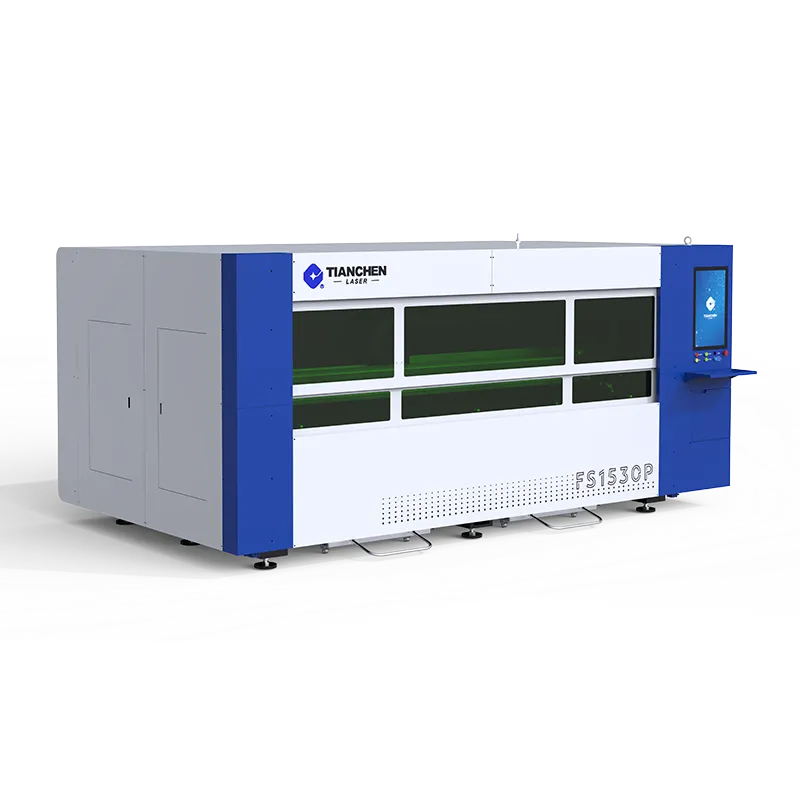

Tianchen Laser, founded in 1995, is a high-tech enterprise specializing in the R&D, production, and sales of intelligent metal forming equipment. With a customer-centric approach and a focus on quality and service, the company has developed a comprehensive range of laser cutting machines perfectly suited for the heavy machinery sector.

The FB12525 large-format laser cutting machine is a standout solution for large-scale heavy machinery components. Designed for industrial projects requiring large-scale metal cutting, it combines immense power with exceptional precision, easily handling the cutting of large structural parts and thick metal plates. For businesses seeking a balance between quality and cost-effectiveness, the NS3015 cost-effective laser cutting machine delivers reliable metal processing at an affordable price, making it ideal for medium-sized heavy machinery manufacturers. The PM3015, representing advanced laser cutting technology, integrates enhanced features that improve productivity and product quality, meeting the high-precision demands of complex heavy machinery components. Meanwhile, the M230 laser cutting machine, with its robust build and efficient cutting mechanism, provides consistent performance for various metal cutting tasks, ensuring durability even in high-intensity production environments.

Beyond individual machines, Tianchen Laser offers integrated metal cutting and automated production line solutions. These solutions seamlessly connect laser cutting equipment with automated tower storage systems, streamlining material unloading, storage, and processing workflows. This integration not only boosts production efficiency but also reduces human error, aligning with the heavy machinery sector’s pursuit of lean manufacturing.

Technological Advantages Backing Reliable Solutions

Tianchen Laser’s ability to deliver top-tier metal cutting solutions stems from its strong technological foundation. The company boasts a professional R&D team that continuously innovates, holding over 20 software copyrights and patents. Its intelligent manufacturing base ensures an annual production capacity of over 10,000 units for main products, guaranteeing timely delivery even for large-scale orders. Adhering to strict quality control standards, every laser cutting machine undergoes rigorous testing before leaving the factory, ensuring long-term reliability in harsh heavy machinery production environments.

With a global presence spanning more than 100 countries and regions, Tianchen Laser understands the diverse needs of customers across different cultural and industrial backgrounds. Its customer-centric service model includes customized solutions, technical support, and after-sales service, ensuring that each client receives personalized assistance tailored to their specific production requirements.

Practical Applications and Customer Value in Heavy Machinery

In the heavy machinery sector, Tianchen Laser’s metal cutting solutions have been widely applied in various fields. In agricultural machinery manufacturing, the high-precision cutting of farm equipment components ensures optimal performance and durability. In the construction machinery industry, the large-format cutting capability of the FB12525 enables efficient production of excavator arms, crane frames, and other large components. In heavy equipment manufacturing, the PM3015’s advanced technology ensures the precision of complex gears and shafts, enhancing the overall reliability of the machinery.

By adopting Tianchen Laser’s metal cutting solutions, heavy machinery manufacturers have achieved significant improvements: production efficiency has increased by up to 30%, material waste has been reduced by 15%, and product defect rates have dropped drastically. These results not only lower production costs but also strengthen the competitiveness of manufacturers in the global market.

Conclusion

As the heavy machinery sector continues to evolve toward high-efficiency, high-quality, and intelligent manufacturing, the demand for advanced metal cutting solutions will only grow. Tianchen Laser, with 29 years of experience in the industry, combines technological innovation, reliable product quality, and global service capabilities to provide heavy machinery manufacturers with comprehensive metal cutting solutions. Whether it’s handling large-scale components, ensuring precision cutting, or integrating automated production lines, Tianchen Laser is committed to supporting the development of the heavy machinery sector and creating greater value for customers worldwide.