1. O Valor Central do Corte a Laser para Metais: Precisão Encontra Eficiência

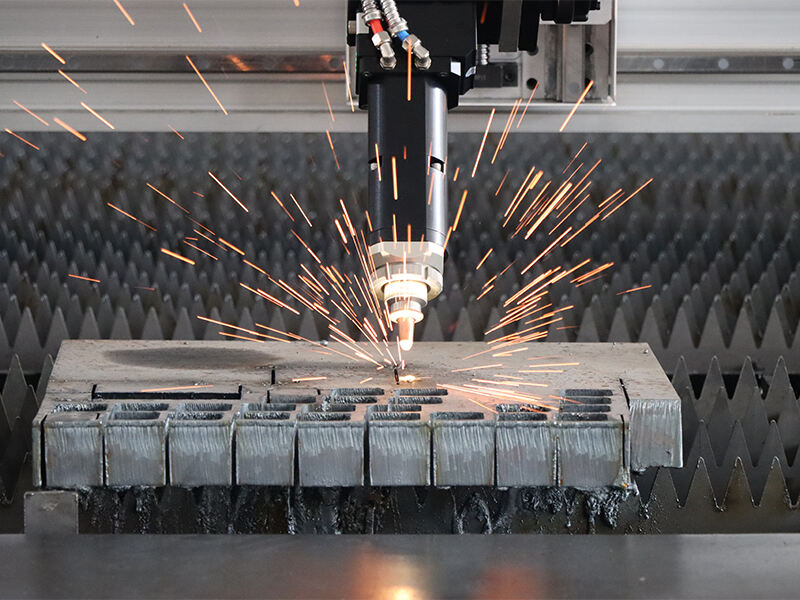

Na paisagem moderna da fabricação, o corte a laser de metais emergiu como uma tecnologia transformadora, com precisão e eficiência sendo suas vantagens centrais insubstituíveis. Diferentemente dos métodos tradicionais de corte, o corte a laser de metais utiliza energia laser concentrada para realizar cortes ultrafinos em diversos materiais metálicos, minimizando o desperdício de material ao mesmo tempo em que garante qualidade de produto consistente. Para indústrias que vão da fabricação de automóveis à maquinaria pesada, essa combinação de precisão e eficiência se traduz diretamente em redução de custos de produção, prazos de entrega mais curtos e maior competitividade no mercado. Como pioneira na indústria a laser, a Tianchen Laser sempre considerou a precisão e a eficiência como a pedra angular do seu desenvolvimento de produtos, oferecendo soluções que atendem aos principais problemas enfrentados pelos fabricantes globais.

2. Vantagens Tecnológicas da Tianchen Laser no Corte a Laser de Metais

Fundada em 1995, a Tianchen Laser acumulou 29 anos de experiência nas áreas de pesquisa, desenvolvimento e produção de equipamentos mecânicos inteligentes. Este longo compromisso com a inovação dotou a empresa de fortes capacidades tecnológicas únicas no corte a laser de metais. A empresa conta com uma equipe profissional de P&D que continuamente desenvolve tecnologias avançadas, como sistemas servo de acompanhamento e funções de sobreposição de grampos frontais, as quais aumentam significativamente a precisão e estabilidade do corte. Com uma base de manufatura inteligente, a Tianchen Laser garante que cada máquina de corte a laser para metal passe por um rigoroso controle de qualidade, alcançando uma capacidade anual de produção superior a 10.000 unidades nos seus principais produtos. Comprometida com o princípio de "orientação pela qualidade e pelo serviço, centrada no cliente", a empresa incorpora a precisão em todas as etapas da produção, desde a seleção dos componentes até a montagem final, e otimiza a eficiência de corte por meio de atualizações tecnológicas — permitindo aos clientes obter maior produtividade com menor consumo de energia.

3. Série de Produtos Personalizada para Diversas Necessidades Industriais

A Tianchen Laser oferece uma gama completa de máquinas de corte a laser para metais, incluindo as séries P, FB, TM e FS, cada uma projetada para atender diferentes cenários industriais. A inovadora Série P, aclamada como "a rainha da eficiência entre produtos similares", destaca-se pelo corte em alta velocidade sem comprometer a precisão, sendo ideal para produção em massa. As máquinas de corte chanfrado da Série FB são conhecidas por sua excepcional precisão e eficiência, atendendo requisitos complexos de processamento nas indústrias de máquinas para construção e automotiva. Para empresas que buscam soluções econômicas, o NS3015 se destaca como uma opção de alta qualidade e acessível, oferecendo desempenho confiável no processamento de metais. O FB12525, um modelo de grande formato, combina potência e precisão para executar tarefas de corte de metais em larga escala em projetos industriais. Enquanto isso, o PM3015 representa a tecnologia a laser de ponta, aumentando a produtividade e a qualidade do produto em aplicações exigentes, e o M230 oferece estrutura robusta e mecanismos de corte eficientes para um desempenho consistente em diversas tarefas de corte de metais. Esses produtos abrangem uma ampla variedade de setores, incluindo maquinário agrícola, máquinas pesadas, fabricação automotiva e indústria da construção, demonstrando a capacidade da Tianchen Laser de fornecer soluções personalizadas.

4. Reconhecimento Global: A Presença no Mercado e a Confiança da Tianchen Laser

Ao longo dos últimos 29 anos, a Tianchen Laser expandiu seus negócios para mais de 100 países e regiões em todo o mundo, conquistando a confiança generalizada de clientes globais. Esse sucesso internacional decorre do compromisso inabalável da empresa com qualidade e serviço. Desde 2019, a empresa obteve mais de 20 direitos autorais de software e patentes e, continuamente desde 2002, recebeu inúmeras honrarias provinciais e nacionais, atestando sua força tecnológica e reputação no setor. Em 2022, suas exportações atingiram 200 milhões de yuans, demonstrando o reconhecimento internacional de seus produtos de corte a laser para metais. Ao atender empresas de pequeno e médio porte ou grandes grupos industriais, a Tianchen Laser mantém o compromisso com entregas rápidas e soluções personalizadas, garantindo que clientes em diferentes regiões e setores recebam suporte adaptado às suas necessidades — consolidando ainda mais sua posição como parceira confiável no mercado global de corte a laser para metais.

5. O Futuro do Corte a Laser em Metal: Inteligência e Personalização

À medida que a indústria de manufatura evolui rumo à inteligência e à automação, a tecnologia de corte a laser em metal também está avançando. A Tianchen Laser está na vanguarda dessa tendência, integrando soluções de linhas de produção automatizadas às suas máquinas de corte a laser. Os equipamentos automáticos de armazenamento em torre da empresa, projetados para funcionar em conjunto com as máquinas de corte a laser, simplificam o descarregamento e o armazenamento de materiais, melhorando ainda mais a eficiência geral da produção. No futuro, a Tianchen Laser continuará focada na inovação tecnológica, explorando mecanismos de corte mais inteligentes e opções de personalização mais flexíveis, atendendo às necessidades em constante evolução dos fabricantes globais. Ao seguir seus valores centrais de precisão e eficiência, a empresa está preparada para liderar o desenvolvimento futuro da indústria de corte a laser em metal, gerando maior valor para clientes em todo o mundo.

Sumário

- 1. O Valor Central do Corte a Laser para Metais: Precisão Encontra Eficiência

- 2. Vantagens Tecnológicas da Tianchen Laser no Corte a Laser de Metais

- 3. Série de Produtos Personalizada para Diversas Necessidades Industriais

- 4. Reconhecimento Global: A Presença no Mercado e a Confiança da Tianchen Laser

- 5. O Futuro do Corte a Laser em Metal: Inteligência e Personalização