In the dynamic world of metal fabrication, fiber laser technology has emerged as a transformative force, and cutting speed stands as a critical determinant of productivity, cost-efficiency, and product quality. For over 29 years, Tianchen Laser has been at the forefront of fiber laser innovation, leveraging its expertise in intelligent metal forming equipment to help manufacturers across more than 100 countries optimize their cutting processes. As a high-tech enterprise with an annual production capacity exceeding 10,000 units, Tianchen Laser’s insights into cutting speeds are rooted in real-world applications and continuous R&D advancements.

The Significance of Cutting Speeds in Fiber Laser Metal Cutting

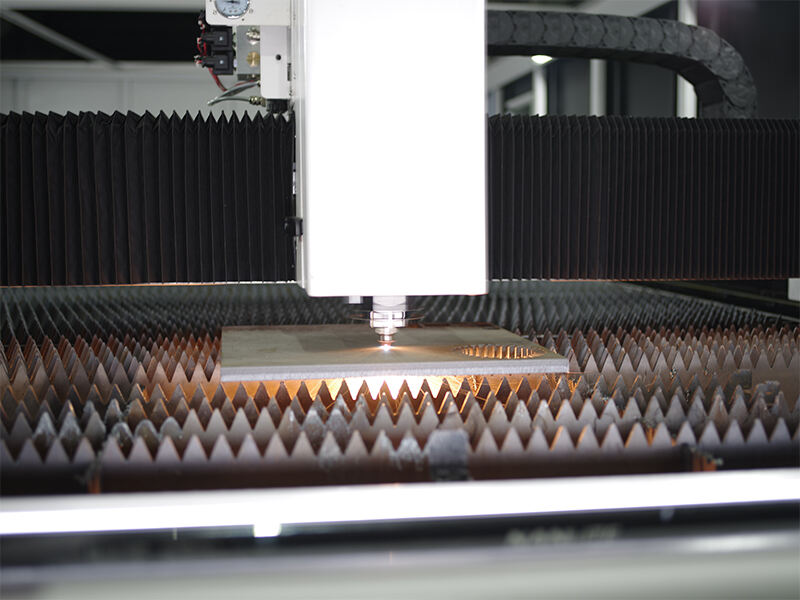

Cutting speed is far more than a numerical value—it directly impacts a manufacturer’s bottom line and competitive edge. In industries ranging from automotive manufacturing to heavy machinery and construction, faster and more precise cutting translates to shorter production cycles, reduced material waste, and the ability to meet tight project deadlines. Tianchen Laser’s experience serving diverse sectors has shown that optimal cutting speeds balance efficiency with precision: too slow, and production costs rise; too fast, and cut quality degrades, leading to rework and material loss. For businesses seeking cost-effective solutions without compromising performance, understanding how cutting speeds align with equipment capabilities is paramount—something Tianchen Laser addresses through models like the NS3015, a cost-effective laser cutting machine designed for quality metal processing at affordable prices.

Key Factors Influencing Fiber Laser Cutting Speeds

Several core factors dictate the maximum achievable cutting speed of a fiber laser system, and Tianchen Laser’s engineering team has refined its products to adapt to these variables:

- Material Properties: Metals with higher thermal conductivity (e.g., aluminum) or thickness require adjusted speeds to ensure clean cuts. Tianchen’s M230 model, with its robust build and efficient cutting mechanism, delivers consistent performance across different metal types by adapting to material-specific thermal demands.

- Laser Power and Beam Quality: Higher laser power enables faster cutting, but beam quality ensures precision. The PM3015, representing Tianchen’s advanced laser cutting technology, integrates enhanced beam control to boost both speed and accuracy—critical for industrial projects where productivity and quality cannot be sacrificed.

- Machine Design and Automation: Intelligent features like servo follow-up and front clamp override (hallmarks of Tianchen’s P Series) minimize downtime and optimize material feeding, directly enhancing cutting speed. Automated tower storage equipment, developed to work in tandem with Tianchen’s laser cutters, streamlines material handling, further accelerating the entire production process.

Optimizing Cutting Speeds: Tianchen Laser’s Technical Expertise

For manufacturers aiming to maximize cutting efficiency, Tianchen Laser offers more than just equipment—it provides customized solutions rooted in 29 years of industry experience. Here’s how Tianchen supports speed optimization:

- R&D-Driven Innovation: With over 20 software copyrights and patents, Tianchen’s professional R&D team continuously refines cutting algorithms to match real-world production needs. The FB Series bevel cutting machines, renowned for precision and efficiency, exemplify how targeted innovation can elevate speed without compromising cut quality.

- Customer-Centered Customization: Every industry and project has unique requirements. Tianchen works closely with clients to tailor laser cutting solutions—whether for large-format industrial projects (addressed by the FB12525 model) or small to medium-scale production—ensuring cutting speeds are optimized for specific use cases.

- Quality Assurance for Sustained Speed: A machine’s ability to maintain consistent cutting speeds over time depends on its build quality. Tianchen’s intelligent manufacturing base adheres to strict quality standards, ensuring that models like the FB12525 (ideal for large-scale metal cutting) retain their power and precision even in high-volume production environments.

Real-World Applications: Cutting Speed Excellence Across Industries

Tianchen Laser’s global footprint spans over 100 countries, with success stories in agricultural machinery, automotive manufacturing, and construction machinery. In the construction machinery sector—where high-efficiency manufacturing is a growing demand—Tianchen’s laser cutters deliver the fast, precise cuts needed to keep up with industry growth. For heavy machinery production, the ability to process thick metals at optimal speeds reduces lead times, while automotive manufacturers benefit from the P Series’ efficiency (dubbed “the king of efficiency among peer products”) to meet high-volume production targets. These applications prove that when cutting speeds are aligned with equipment capabilities and industry needs, manufacturers gain a tangible competitive advantage—one Tianchen Laser has helped thousands of businesses achieve.

In conclusion, cutting speed is a cornerstone of fiber laser technology, and mastering it requires a deep understanding of equipment, materials, and industry demands. Tianchen Laser’s 29-year legacy of focusing on quality and service, combined with its global expertise and innovative product lineup, positions it as a trusted partner for manufacturers seeking to optimize cutting speeds. Whether through cost-effective models, advanced high-power systems, or customized solutions, Tianchen Laser empowers businesses worldwide to achieve faster, more precise, and more efficient metal cutting—driving success in an increasingly competitive market.