In the global pursuit of carbon neutrality and green development, sustainable manufacturing has evolved from a corporate social responsibility initiative to a core competitive advantage. As a key driver of intelligent metal processing, laser cutting machines are reshaping the production paradigm with their high efficiency, precision, and environmental friendliness. Tianchen Laser, a seasoned high-tech enterprise with 29 years of experience in the industry, has integrated sustainable development concepts into every link of its product R&D and production, making its laser cutting solutions a powerful enabler for enterprises worldwide to achieve green manufacturing goals.

1. The Core Demands of Sustainable Manufacturing and the Alignment with Laser Technology

Sustainable manufacturing focuses on three core pillars: minimizing resource waste, reducing energy consumption, and lowering environmental emissions. Traditional metal cutting methods such as plasma cutting and flame cutting often suffer from low material utilization rates, high energy consumption, and significant pollutant emissions, which are incompatible with the development trend of green production. In contrast, laser cutting technology inherently meets the requirements of sustainable manufacturing.

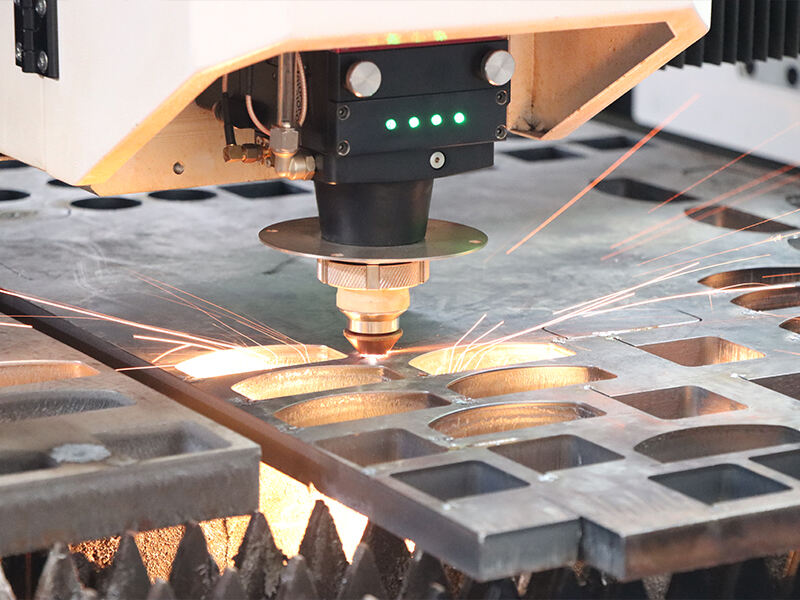

Laser cutting uses a focused high-energy laser beam to melt or vaporize metal materials, avoiding the material loss caused by mechanical force in traditional cutting. For enterprises, this means higher material utilization rates and reduced waste disposal costs. Tianchen Laser has always adhered to the concept of "technology serving sustainability" and has continuously optimized its laser cutting systems. Its products, from the cost-effective NS3015 model to the high-performance PM3015, all adopt energy-saving laser sources and intelligent control systems, which can reduce energy consumption by 30% compared with conventional laser cutting equipment of the same type.

2. Three Core Advantages of Tianchen Laser Cutting Machines in Promoting Sustainable Manufacturing

Tianchen Laser's leading position in the field of sustainable manufacturing stems from its in-depth understanding of industry needs and continuous technological innovation. Its laser cutting machines have three core advantages that effectively drive green production.

Firstly, high precision reduces material waste. The FB series bevel cutting machines and TM series laser cutting equipment independently developed by Tianchen Laser feature advanced servo follow-up and front clamp override technologies, achieving cutting precision up to ±0.03mm. In large-scale metal processing projects such as construction machinery and automotive manufacturing, this high precision ensures that each sheet of metal is fully utilized, reducing material waste by more than 15% compared with traditional cutting methods.

Secondly, efficient operation lowers carbon emissions. With an annual production capacity of over 10,000 units, Tianchen Laser's intelligent manufacturing base adopts automated production lines to ensure the stability and efficiency of its products. The M230 model, known for its robust build and efficient cutting mechanism, can complete the processing of a single workpiece 50% faster than traditional equipment. Higher production efficiency means shorter working hours for equipment, thereby reducing carbon emissions generated during operation.

Thirdly, modular design supports circular production. Tianchen Laser's product line covers a full range of models, including the large-format FB12525 suitable for industrial large-scale projects and the flexible FS series. These products adopt a modular design, which facilitates maintenance and component replacement, extending the service life of the equipment. At the same time, the company provides customized solutions according to customer needs, avoiding the waste of resources caused by over-equipment configuration.

3. Sustainable Value Implementation in Cross-Industry Applications

Tianchen Laser's laser cutting solutions have been widely applied in agricultural machinery, heavy machinery, automotive manufacturing, and construction industries, delivering tangible sustainable value to customers in various fields.

In the automotive manufacturing industry, lightweight materials such as aluminum alloys and high-strength steel are increasingly used to reduce vehicle energy consumption. Tianchen Laser's high-precision laser cutting machines can accurately process these special materials, ensuring the structural strength of auto parts while minimizing material waste. This not only helps automakers meet environmental protection standards but also reduces production costs.

In the construction industry, the demand for large-scale and high-precision metal components is growing. The FB12525 large-format laser cutting machine can efficiently process large-size metal plates, reducing the number of welding joints and improving the structural stability of components. Moreover, the precise cutting effect reduces on-site modification and waste during construction, contributing to green construction.

4. Future Trends: Deep Integration of Laser Technology and Sustainable Manufacturing

As global environmental regulations become increasingly strict, the integration of laser cutting technology and sustainable manufacturing will deepen. Tianchen Laser, which has obtained more than 20 software copyrights and patents since 2019, will continue to focus on technological innovation. Future R&D directions will include more energy-efficient laser sources, AI-driven intelligent cutting path optimization, and deeper integration with automated storage and logistics systems.

Adhering to the principle of quality and service orientation and customer-centered approach, Tianchen Laser has expanded its business to more than 100 countries and regions. In the future, the company will continue to leverage its technological advantages and global resource layout to provide more efficient and environmentally friendly laser cutting solutions for enterprises around the world, contributing to the sustainable development of the global manufacturing industry.