Metal cutting is the backbone of global manufacturing, powering industries from automotive production to construction machinery and agricultural equipment. For decades, manufacturers relied on traditional methods like plasma cutting and flame cutting, but these technologies often fell short in precision, efficiency, and environmental friendliness. As the demand for high-quality, cost-effective metal processing grows, fiber laser cutting has emerged as a game-changer, redefining the standards of modern metal fabrication.

The Evolution of Metal Cutting: From Traditional Methods to Modern Innovation

Traditional metal cutting technologies have served the manufacturing industry for years, but their limitations have become increasingly apparent in today’s fast-paced, quality-driven market. Plasma cutting, while versatile, struggles with narrow kerf widths and consistent edge quality, especially when processing thin or high-strength metals. Flame cutting, on the other hand, consumes excessive energy and generates significant waste, failing to meet the sustainability goals of contemporary enterprises. These pain points created an urgent need for a more advanced solution—and fiber laser cutting stepped in to fill the gap.

Core Advantages of Fiber Laser Cutting That Transform Manufacturing

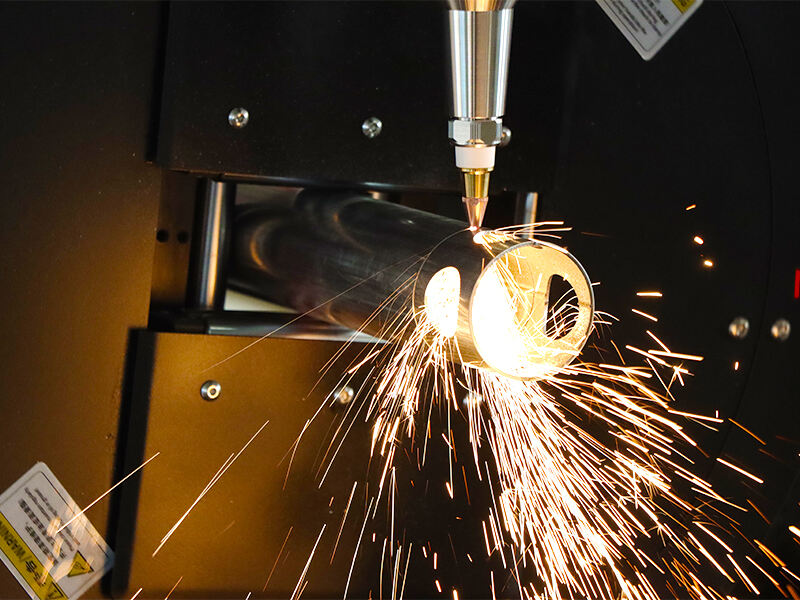

Fiber laser cutting stands out for its unparalleled combination of precision, efficiency, and flexibility, making it the preferred choice for metal processing. Unlike traditional methods, fiber lasers deliver a concentrated beam of light that melts or vaporizes metal with minimal heat affected zone (HAZ), ensuring clean, burr-free edges and reducing post-processing work. This precision is critical for industries like automotive manufacturing and heavy machinery, where component accuracy directly impacts product performance.

Additionally, fiber laser cutting machines operate at significantly higher speeds than plasma or flame cutters, boosting production throughput without compromising quality. For manufacturers aiming to scale operations, this efficiency translates to lower per-unit costs and faster time-to-market. Energy efficiency is another key advantage: fiber lasers consume up to 70% less energy than traditional cutting technologies, aligning with global efforts to reduce carbon footprints. Their ability to cut a wide range of metals—from mild steel and aluminum to stainless steel and copper—adds to their versatility, catering to diverse industry needs.

Tianchen Laser: A Pioneer in Fiber Laser Metal Cutting Solutions

Since its establishment in 1995, Tianchen Laser has been at the forefront of intelligent metal forming equipment innovation, specializing in the R&D, production, and sales of fiber laser cutting machines and automated production line solutions. As a high-tech enterprise with an intelligent manufacturing base, the company boasts an annual production capacity of over 10,000 units, enabling it to meet the growing global demand for high-quality metal processing equipment.

Tianchen Laser’s success stems from its unwavering commitment to quality, service, and customer-centricity. With a professional R&D team, the company has secured over 20 software copyrights and patents, continuously enhancing the performance of its fiber laser cutting solutions. Its products are designed to deliver consistent reliability, whether for small-batch customization or large-scale industrial production. Operating in more than 100 countries and regions, Tianchen Laser understands the unique needs of diverse markets, offering tailored solutions that adapt to different industrial contexts and quality standards.

The Future: Fiber Lasers Integrated with Smart Automation

The future of metal cutting lies in the integration of fiber laser technology with smart automation—and Tianchen Laser is leading this transformation. Automated production line solutions, when combined with fiber laser cutting machines, streamline material handling, reduce human error, and maximize production efficiency. Tianchen Laser’s intelligent manufacturing base is equipped to develop and produce integrated solutions that connect fiber laser cutters with automated storage and retrieval systems, creating seamless, end-to-end production workflows.

As sustainability becomes a top priority for manufacturers worldwide, fiber laser cutting will continue to gain traction due to its low energy consumption and minimal waste. Tianchen Laser remains committed to innovation, investing in R&D to enhance the performance of its fiber laser products and develop more eco-friendly, intelligent solutions. With its decades of experience and global expertise, the company is well-positioned to shape the future of metal cutting, empowering manufacturers to achieve greater productivity, quality, and competitiveness.

In conclusion, fiber laser cutting is not just a trend—it is the future of metal processing. Its unmatched advantages, combined with the expertise and global reach of companies like Tianchen Laser, are driving a revolution in manufacturing. As industries evolve, fiber laser technology will remain at the core of efficient, precise, and sustainable metal cutting, paving the way for a new era of industrial innovation.