Metal cutting is a cornerstone of global manufacturing, and as industries demand higher precision, efficiency, and flexibility, fiber laser technology has emerged as a transformative force. For nearly three decades, Tianchen Laser has been at the forefront of this evolution, blending technological innovation with customer-centric solutions to redefine the possibilities of metal cutting. Today, fiber laser technology is not just a tool but a driver of industrial progress, and understanding its innovations is key to unlocking the future of manufacturing.

1. The Evolution of Fiber Laser Technology in Metal Cutting

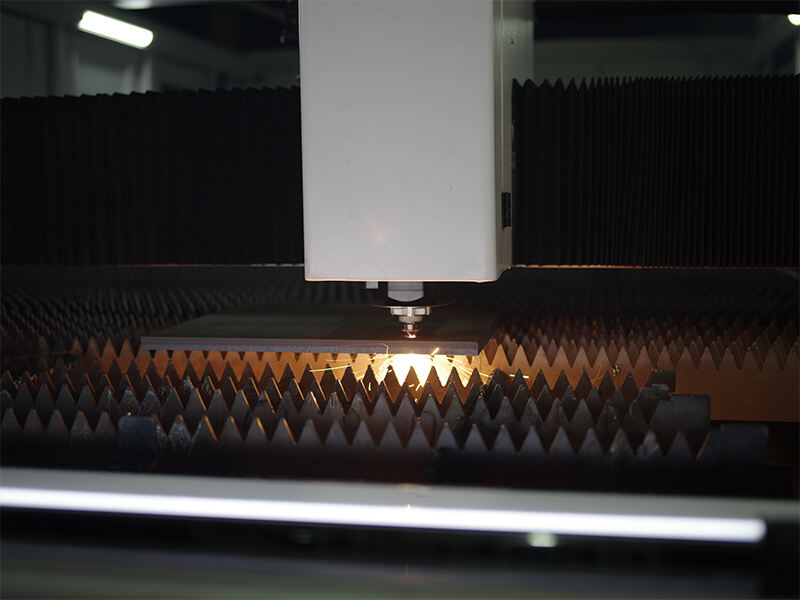

The journey of fiber laser technology in metal cutting has been marked by continuous breakthroughs, and Tianchen Laser has been a pivotal contributor since its establishment in 1995. Unlike traditional cutting methods such as plasma or mechanical cutting, fiber laser cutting leverages concentrated light energy to melt or vaporize metal, offering unmatched precision and speed. Over the years, Tianchen Laser’s R&D team has refined this technology, addressing pain points like thick metal processing, edge quality, and energy consumption.

With an intelligent manufacturing base and an annual production capacity exceeding 10,000 units, Tianchen Laser has scaled its innovations to meet global demand. From the early days of basic metal cutting to today’s automated production lines, fiber laser technology has evolved to handle diverse materials—from stainless steel and aluminum to high-strength alloys—making it indispensable in industries ranging from automotive manufacturing to heavy machinery.

2. Key Innovations Driving Tianchen Laser’s Leadership

Tianchen Laser’s success in fiber laser metal cutting stems from its focus on targeted innovations that solve real-world manufacturing challenges. One of its standout achievements is the development of specialized product series, each tailored to distinct industrial needs. The P Series, hailed as “the king of efficiency among peer products,” integrates advanced servo follow-up technology and front clamp override, ensuring seamless cutting even for complex workpieces. For businesses seeking cost-effective solutions without compromising quality, the NS3015 model delivers reliable performance at an affordable price, democratizing access to fiber laser technology.

For large-scale industrial projects, the FB12525 large-format laser cutting machine combines power and precision, tackling massive metal sheets with ease—an essential capability for the construction and heavy machinery industries. The PM3015, representing Tianchen Laser’s cutting-edge technology, enhances productivity through intelligent features that optimize cutting paths and reduce material waste. Beyond hardware, the company has secured over 20 software copyrights and patents, integrating digitalization into its fiber laser systems to enable real-time monitoring and process optimization.

Another critical innovation is the synergy between fiber laser cutting machines and automated production solutions, such as automated tower storage equipment. This integration streamlines material handling, from unloading to storage, minimizing downtime and boosting overall production efficiency—aligning with the global trend toward smart manufacturing.

3. How Fiber Laser Innovations Transform Industrial Applications

The impact of fiber laser technology extends far beyond the workshop floor, revolutionizing key industries that rely on metal cutting. In automotive manufacturing, precision is non-negotiable, and Tianchen Laser’s fiber laser machines deliver consistent cuts for engine components, chassis parts, and body structures, supporting the production of safer and more efficient vehicles. The agricultural machinery industry benefits from the technology’s ability to cut thick metal parts for tractors and harvesters, ensuring durability in harsh working conditions.

In the construction industry, where large-format metal pieces are common, the FB12525’s capabilities enable the fabrication of structural steel and construction machinery components with tight tolerances, accelerating project timelines. For heavy machinery manufacturers, the robustness of Tianchen Laser’s fiber laser systems—exemplified by the M230 model’s robust build and efficient cutting mechanism—ensures reliability even for high-volume production runs.

What makes these innovations globally relevant is Tianchen Laser’s commitment to customization. By offering tailored fiber laser solutions, the company caters to the unique needs of over 100 countries and regions, adapting to different manufacturing standards and material requirements. This flexibility, combined with fast delivery and quality assurance, has made Tianchen Laser a trusted partner for businesses worldwide.

4. The Future Outlook: Sustainability and Customization

As the manufacturing industry shifts toward sustainability and personalized production, fiber laser technology is poised to play an even more critical role. Tianchen Laser is already aligning its innovations with this future, focusing on energy-efficient fiber laser systems that reduce carbon footprints without sacrificing performance. Additionally, the demand for customized products is driving the development of more flexible fiber laser solutions—machines that can quickly switch between cutting tasks, accommodate small-batch production, and adapt to design changes in real time.

Tianchen Laser’s customer-centric approach positions it well to lead this next phase of evolution. By prioritizing quality and service, the company continues to expand its global footprint, bringing fiber laser innovations to emerging markets and established industrial hubs alike. The future of metal cutting will be defined by seamless integration of fiber laser technology with automation, AI, and sustainability—and Tianchen Laser is laying the groundwork for this future through continuous R&D and a deep understanding of customer needs.

In conclusion, fiber laser technology has redefined metal cutting, and Tianchen Laser’s three decades of innovation have been instrumental in this transformation. From cost-effective models to large-format, high-precision systems, the company’s fiber laser solutions empower manufacturers to achieve more—faster, more accurately, and more sustainably. As industries evolve, Tianchen Laser remains committed to pushing the boundaries of fiber laser technology, ensuring that the future of metal cutting is not just innovative, but also inclusive and efficient for businesses around the world.