Introduction: The Critical Role of Laser Cutting Machines in Modern Manufacturing

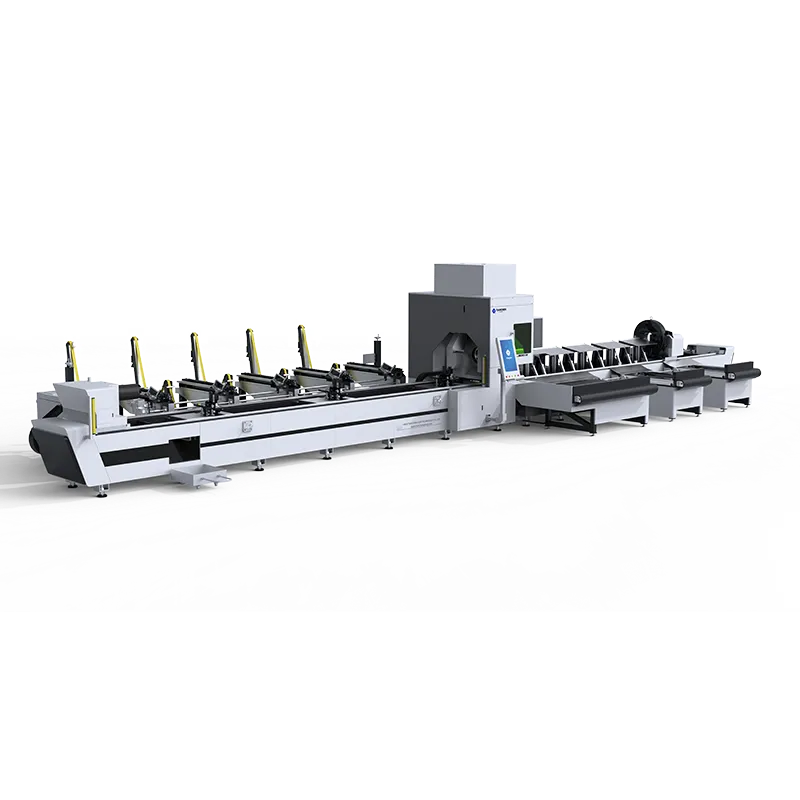

In the fast-paced world of metal fabrication, the choice of a laser cutting machine directly impacts production efficiency, product quality, and long-term business profitability. As a core equipment in metal processing, a well-suited laser cutting machine can optimize workflow, reduce material waste, and enhance market competitiveness. Founded in 1995, Tianchen Laser has been deeply engaged in the laser industry for 29 years, evolving into a high-tech enterprise specializing in intelligent metal forming equipment. With its business expanding to over 100 countries and regions, the company has accumulated rich experience in meeting diverse customer needs, making it a reliable reference for businesses seeking the right laser cutting solutions.

Core Considerations for Choosing a Laser Cutting Machine

1. Define Your Specific Cutting Requirements

The first step in selecting a laser cutting machine is to clarify your actual production needs. Different materials (such as carbon steel, aluminum alloy, and stainless steel) and thicknesses require machines with varying power and cutting mechanisms. For example, thin-sheet metal processing may prioritize speed and precision, while thick-plate cutting demands higher power output. Additionally, the precision requirements of finished products—whether for high-precision automotive parts or general construction components—determine the technical parameters of the machine. Tianchen Laser’s product lineup, including the high-precision PM3015 and cost-effective NS3015, covers a wide range of cutting scenarios to meet different precision and material processing needs.

2. Align with Production Scale and Capacity

Your business’s production volume and growth plans are key factors in machine selection. Small and medium-sized enterprises with moderate output may benefit from cost-effective models that balance performance and budget, such as Tianchen Laser’s NS3015. For large-scale industrial production with high-volume demands, machines with high efficiency and stable continuous operation are essential. Tianchen Laser boasts an intelligent manufacturing base with an annual production capacity of over 10,000 units, and its P Series—hailed as the "king of efficiency among peer products"—and FB Series bevel cutting machines can fully meet the high-capacity production needs of large enterprises.

3. Balance Budget and Long-Term Value

While budget constraints are unavoidable, focusing solely on initial costs can lead to higher maintenance or replacement expenses later. A cost-effective laser cutting machine should combine reasonable pricing with reliable quality, low maintenance costs, and long service life. Tianchen Laser adheres to a quality-oriented philosophy, ensuring that each product undergoes strict quality control. The M230 model, for instance, features a robust build and efficient cutting mechanism, providing consistent performance for long-term use and delivering greater value over time.

Industry-Specific Laser Cutting Machine Selection

1. Agricultural Machinery Industry

Agricultural machinery parts often require resistance to harsh working conditions, so the laser cutting machine must be durable and adaptable. Tianchen Laser’s M230 is an ideal choice, with its sturdy structure and stable cutting performance enabling it to handle various metal processing tasks for agricultural equipment, ensuring product reliability.

2. Automotive Manufacturing Industry

The automotive industry demands ultra-high precision and efficiency for parts processing. Tianchen Laser’s PM3015, equipped with advanced laser cutting technology, enhances processing accuracy and productivity, perfectly matching the strict quality requirements of automotive manufacturing. Its ability to achieve precise cutting of complex components helps automakers improve product quality and production efficiency.

3. Construction and Heavy Machinery Industry

Large-scale metal structures in construction and heavy machinery require large-format cutting capabilities. Tianchen Laser’s FB12525 large-format laser cutting machine combines power and precision, making it suitable for large-scale metal cutting projects in these industries. It efficiently processes large-sized workpieces while ensuring cutting accuracy, meeting the needs of high-efficiency and high-quality manufacturing.

Why Tianchen Laser Stands Out as Your Trusted Partner

1. 29 Years of Technical Expertise and Innovation

Since its establishment in 1995, Tianchen Laser has continuously invested in research and development, accumulating over 20 software copyrights and patents. With a professional R&D team, the company stays at the forefront of laser technology, continuously innovating product functions and performance to meet the evolving needs of the metal fabrication industry.

2. Global-Proven Quality and Production Capacity

Tianchen Laser’s intelligent manufacturing base ensures strict quality control and efficient production. With an annual output of over 10,000 units, the company can meet the large-scale supply needs of global customers. Its products have been tested in markets across more than 100 countries and regions, earning widespread recognition for their reliability and performance.

3. Customer-Centric Customized Solutions

Adhering to a customer-centered approach, Tianchen Laser provides customized solutions tailored to the specific needs of different businesses. Whether it’s adjusting machine parameters for special materials or designing automated production line solutions, the company’s professional team works closely with customers to ensure the equipment perfectly fits their production processes.

4. Comprehensive After-Sales Support

Tianchen Laser values long-term cooperation with customers, offering comprehensive after-sales services including technical support, maintenance guidance, and fast delivery. Its global service network ensures that customers in any region can receive timely assistance, minimizing production downtime.

Conclusion: Make an Informed Decision for Sustainable Development

Selecting the right laser cutting machine is a strategic investment that affects your business’s development trajectory. By clarifying cutting requirements, aligning with production scale, balancing budget and value, and considering industry-specific needs, you can find the optimal solution. With 29 years of experience, global quality certification, customized services, and reliable support, Tianchen Laser is committed to providing businesses with high-quality laser cutting machines and comprehensive solutions. Choose Tianchen Laser to empower your metal processing operations and achieve sustainable growth in the competitive market.

Table of Contents

- Introduction: The Critical Role of Laser Cutting Machines in Modern Manufacturing

- Core Considerations for Choosing a Laser Cutting Machine

- Industry-Specific Laser Cutting Machine Selection

- Why Tianchen Laser Stands Out as Your Trusted Partner

- Conclusion: Make an Informed Decision for Sustainable Development