1. The Core Value of Metal Laser Cutting: Precision Meets Efficiency

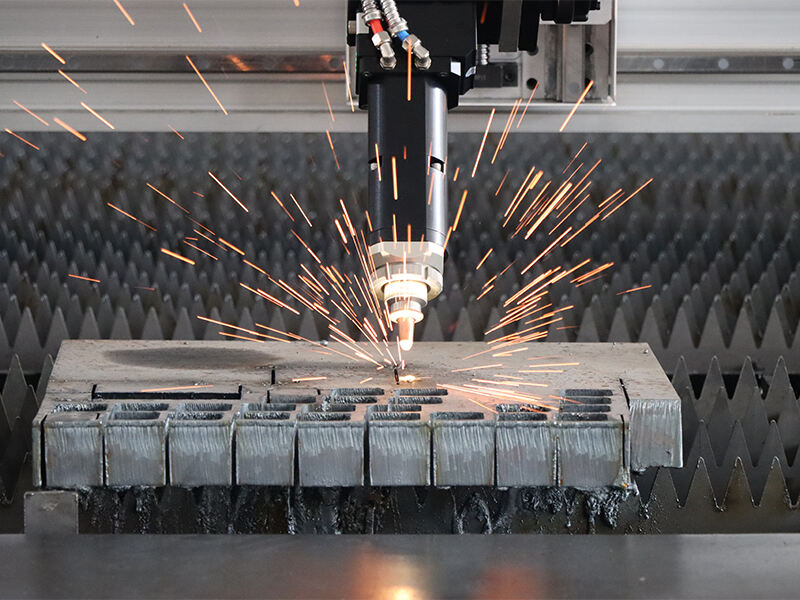

In the modern manufacturing landscape, metal laser cutting has emerged as a transformative technology, with precision and efficiency standing as its irreplaceable core advantages. Unlike traditional cutting methods, metal laser cutting leverages concentrated laser energy to achieve ultra-fine cuts on various metal materials, minimizing material waste while ensuring consistent product quality. For industries ranging from automotive manufacturing to heavy machinery, this combination of precision and efficiency directly translates to reduced production costs, shortened lead times, and enhanced market competitiveness. As a pioneer in the laser industry, Tianchen Laser has always taken precision and efficiency as the cornerstone of its product development, delivering solutions that address the core pain points of global manufacturers.

2. Tianchen Laser’s Technological Advantages in Metal Laser Cutting

Founded in 1995, Tianchen Laser has accumulated 29 years of experience in the research, development, and production of intelligent mechanical equipment. This long-standing commitment to innovation has equipped the company with unique technological strengths in metal laser cutting. The company boasts a professional R&D team that continuously pioneers advanced technologies, such as servo follow-up systems and front clamp override functions, which significantly enhance cutting precision and stability. With an intelligent manufacturing base, Tianchen Laser ensures that each metal laser cutting machine undergoes strict quality control, resulting in an annual production capacity of over 10,000 units for its main products. Adhering to the principle of "quality and service orientation, customer-centered approach," the company integrates precision into every link of production, from component selection to final assembly, and optimizes cutting efficiency through technological upgrades—enabling customers to achieve higher productivity with lower energy consumption.

3. Product Series Tailored for Diverse Industrial Needs

Tianchen Laser offers a full range of metal laser cutting machines, including the P Series, FB Series, TM Series, and FS Series, each designed to meet diverse industrial scenarios. The all-new P Series, hailed as "the king of efficiency among peer products," excels in high-speed cutting without compromising precision, making it ideal for mass production. The FB Series bevel cutting machines are renowned for their exceptional precision and efficiency, catering to complex processing requirements in the construction machinery and automotive industries. For businesses seeking cost-effective solutions, the NS3015 stands out as a high-quality yet affordable option, delivering reliable metal processing performance. The FB12525, a large-format model, combines power and precision to tackle large-scale metal cutting tasks in industrial projects. Meanwhile, the PM3015 represents cutting-edge laser technology, enhancing productivity and product quality for demanding applications, and the M230 offers robust build and efficient cutting mechanisms for consistent performance across various metal cutting tasks. These products cover a wide range of industries, including agricultural machinery, heavy machinery, automotive manufacturing, and the construction industry, demonstrating Tianchen Laser’s ability to provide customized solutions.

4. Global Recognition: Tianchen Laser’s Market Footprint and Trust

Over the past 29 years, Tianchen Laser has expanded its business to more than 100 countries and regions worldwide, earning widespread trust from global customers. This global success stems from the company’s unwavering focus on quality and service. The company has obtained over 20 software copyrights and patents since 2019 and has continuously received numerous provincial and national honors since 2002, testifying to its technological strength and industry reputation. In 2022, its exports reached 200 million yuan, a testament to the international recognition of its metal laser cutting products. Whether serving small and medium-sized enterprises or large industrial groups, Tianchen Laser adheres to fast delivery and customized solutions, ensuring that customers in different regions and industries receive tailored support—further solidifying its position as a reliable partner in the global metal laser cutting market.

5. The Future of Metal Laser Cutting: Intelligence and Customization

As the manufacturing industry evolves towards intelligence and automation, metal laser cutting technology is also advancing. Tianchen Laser is at the forefront of this trend, integrating automated production line solutions with its laser cutting machines. The company’s automated tower storage equipment, designed to work in tandem with laser cutting machines, simplifies material unloading and storage, further improving overall production efficiency. Looking ahead, Tianchen Laser will continue to focus on technological innovation, exploring smarter cutting mechanisms and more flexible customization options to meet the evolving needs of global manufacturers. By adhering to its core values of precision and efficiency, the company is poised to lead the future development of the metal laser cutting industry, bringing greater value to customers worldwide.

Table of Contents

- 1. The Core Value of Metal Laser Cutting: Precision Meets Efficiency

- 2. Tianchen Laser’s Technological Advantages in Metal Laser Cutting

- 3. Product Series Tailored for Diverse Industrial Needs

- 4. Global Recognition: Tianchen Laser’s Market Footprint and Trust

- 5. The Future of Metal Laser Cutting: Intelligence and Customization