Introduction: The Transformative Role of Precision Laser Cutting in Metal Fabrication

In the fast-paced world of manufacturing, precision and efficiency are the cornerstones of success, especially when it comes to cutting metallic materials. As industries ranging from automotive manufacturing to heavy machinery demand higher accuracy, faster production cycles, and greater versatility, laser-based cutting solutions have emerged as the gold standard. Unlike traditional cutting methods, laser cutting technology offers unparalleled control over material processing, making it indispensable for modern metal fabrication. For over 29 years, Tianchen Laser has been at the forefront of this technological revolution, delivering high-quality laser cutting solutions that meet the evolving needs of global customers.

Core Advantages of Laser-Based Metal Cutting Solutions

Unmatched Precision for Complex Metal Components

Precision is non-negotiable in metal cutting, and laser-based solutions excel in this critical aspect. Laser cutting systems use concentrated light energy to slice through metallic materials with micron-level accuracy, ensuring consistent results even for complex geometries and intricate designs. This level of precision eliminates material waste and reduces the need for post-processing, saving both time and costs for manufacturers. Whether it’s thin sheets or thick plates, laser cutting maintains stability and accuracy, making it ideal for producing high-precision components in industries like aerospace and automotive manufacturing.

Enhanced Efficiency and Production Scalability

Laser cutting solutions are designed for efficiency, outperforming traditional cutting methods in speed and throughput. With advanced cutting mechanisms and servo follow-up technology, modern laser machines can handle high-volume production without compromising quality. Tianchen Laser’s equipment, for instance, boasts an annual production capacity of over 10,000 units, enabling businesses to scale their operations seamlessly. The fast cutting speed not only shortens production cycles but also increases overall productivity, helping manufacturers meet tight deadlines and gain a competitive edge in the market.

Versatility Across Metallic Materials and Industries

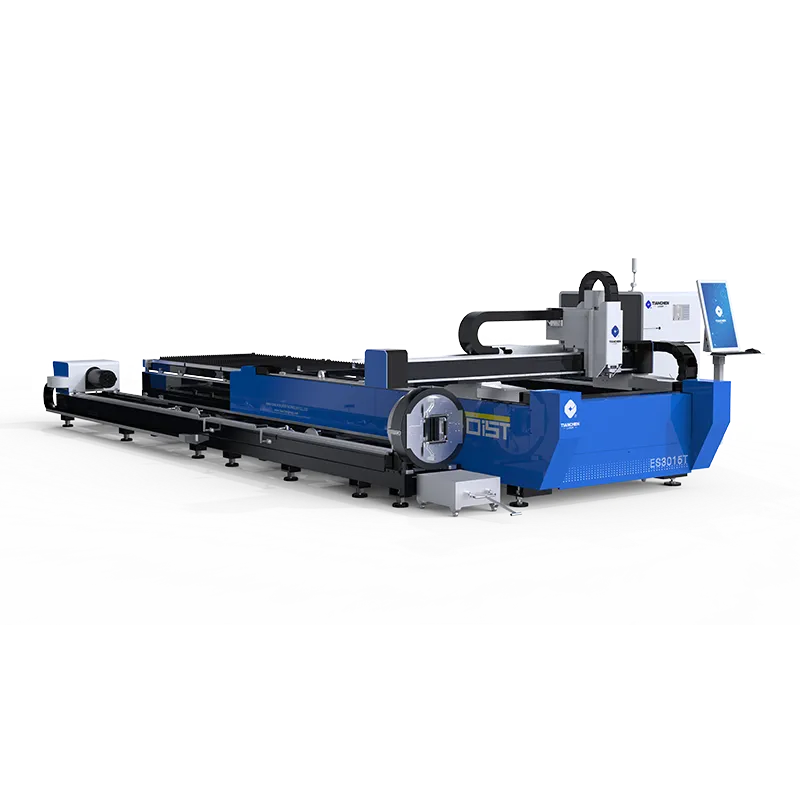

One of the key strengths of laser-based metal cutting is its versatility. It can process a wide range of metallic materials, including steel, aluminum, copper, and alloy metals, adapting to the unique requirements of different industries. From agricultural machinery parts to construction equipment components, laser cutting solutions provide tailored results for every application. Tianchen Laser’s full range of products, such as the cost-effective NS3015, reliable M230, and large-format FB12525, cater to diverse needs, whether it’s small-batch production or large-scale industrial projects.

Tianchen Laser: A Trusted Provider of Precision Cutting Solutions

Decades of Expertise Since 1995

Founded in 1995, Tianchen Laser is a high-tech enterprise with a rich legacy in research, development, production, and sales of intelligent metal forming equipment. Over the past 29 years, the company has grown rapidly, establishing itself as a leading player in the laser industry. With a customer-centered approach and a focus on quality and service, Tianchen Laser has expanded its business to more than 100 countries and regions worldwide, earning the trust of global clients.

Comprehensive Product Line for Diverse Needs

Tianchen Laser offers a full range of laser cutting machines, including the P Series, FB Series, TM Series, and FS Series, each designed to address specific manufacturing challenges. The P Series is hailed as the “King of Efficiency” among peer products, while the FB Series bevel cutting machines are renowned for their precision and efficiency. The NS3015 stands out as a cost-effective option for businesses seeking quality metal processing at an affordable price, and the PM3015 represents advanced laser cutting technology that enhances productivity and quality. This diverse product portfolio ensures that every customer finds a tailored solution for their metallic material cutting needs.

Technological Innovation and Quality Assurance

Innovation is at the heart of Tianchen Laser’s success. The company boasts a professional R&D team that continuously develops new technologies and improves existing products. To date, Tianchen Laser has obtained over 20 software copyrights and patents, reflecting its commitment to technological advancement. Additionally, the company owns an intelligent manufacturing base, implementing strict quality control measures to ensure that every product meets the highest standards. This dedication to quality and innovation has earned Tianchen Laser numerous provincial and national honors over the years.

Industry-Specific Applications of Tianchen’s Laser Cutting Systems

Tianchen Laser’s laser cutting solutions are widely used across various industries, driving efficiency and precision in manufacturing. In the agricultural machinery industry, the high-precision cutting technology ensures the reliability of critical components. For the heavy machinery sector, the robust build of machines like the M230 provides consistent performance for demanding tasks. In automotive manufacturing, the precision of laser cutting contributes to the production of high-quality vehicle parts. The construction industry also benefits from large-format machines like the FB12525, which handle large-scale metal cutting for construction equipment with ease.

Why Choose Tianchen Laser for Your Metal Cutting Requirements?

Choosing the right laser cutting solution provider is crucial for business success. Tianchen Laser offers several compelling advantages: its decades of industry experience, comprehensive product line, technological innovation, and global service network. The company’s annual production capacity of over 10,000 units ensures fast delivery, while its customer-centered approach guarantees personalized solutions and excellent after-sales service. Whether you’re a small business or a large enterprise, Tianchen Laser’s laser-based cutting solutions provide the precision, efficiency, and versatility you need to stay ahead in the competitive manufacturing landscape.

Conclusion: Embracing Precision with Laser Cutting Technology

As metallic material cutting demands continue to evolve, laser-based solutions remain the most reliable and efficient choice for manufacturers worldwide. Tianchen Laser, with its 29 years of expertise, innovative products, and commitment to quality and service, is poised to be your trusted partner in precision metal cutting. By choosing Tianchen Laser’s laser cutting solutions, you’re not just investing in equipment—you’re investing in enhanced productivity, reduced costs, and long-term business success. Embrace the future of metal fabrication with precision laser cutting technology from Tianchen Laser.

Table of Contents

- Introduction: The Transformative Role of Precision Laser Cutting in Metal Fabrication

- Core Advantages of Laser-Based Metal Cutting Solutions

- Tianchen Laser: A Trusted Provider of Precision Cutting Solutions

- Industry-Specific Applications of Tianchen’s Laser Cutting Systems

- Why Choose Tianchen Laser for Your Metal Cutting Requirements?

- Conclusion: Embracing Precision with Laser Cutting Technology